Situated in Germantown, Wisconsin, US, the Great Lakes Packaging Division of Green Bay Packaging (GBP), is undergoing an expansion to boost production capacity and streamline operations.

The ground-breaking ceremony for the new facility took place in July 2024, with the project expected to be completed by 2025.

The new facility will create 20 additional jobs, benefiting both GBP and the surrounding region.

Location of GBP’s expansion project

The new facility will sit on a 52-acre (21ha) site off Highway 41 and Holy Hill Road, along the Holy Hill corridor in the Village of Germantown, Washington County, Wisconsin.

The project is part of an effort by the Village of Germantown to promote business growth in the region.

Great Lakes Packaging Division expansion details

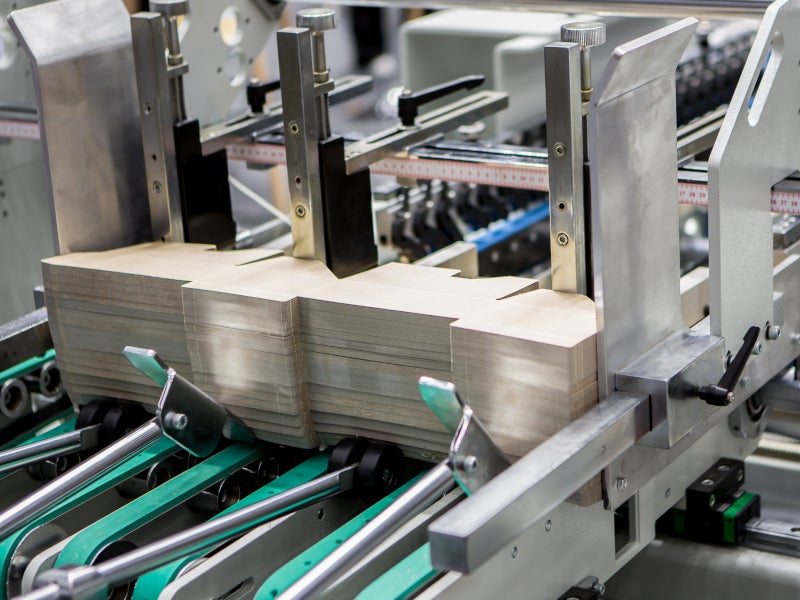

GBP’s Great Lakes Packaging Division expansion will add 270,000ft² (25,084m²) of manufacturing space and feature advanced equipment such as a six-colour plus one-colour inside rotary die cutter (RDC), a litho laminator, and a speciality folder gluer.

The enhancements will significantly improve the division’s capabilities and operational efficiencies to meet customer requirements more effectively.

The facility will not only serve as a functional space but also as an architectural statement, highlighting innovative design and modern aesthetics with its distinctive structure and seamless integration into the surrounding landscape.

Great Lakes Packaging Division details

Certified by the International Safe Transit Association (ISTA) and the Sustainable Forestry Initiative (SFI), the Great Lakes Packaging Division offers a range of innovative products, including corrugated containers, point-of-purchase displays, wood/foam speciality packaging and other products tailored to client requirements.

The division also provides contract packaging and fulfilment services, aiming to deliver comprehensive solutions for packaging and retail needs.

The facility leverages innovative design, consumer science, and extensive manufacturing capabilities to offer effective merchandising solutions. It features large-format capabilities in high-speed digital printing, flexo, and litho mounting, ensuring cost-effective and timely production.

The digital printer is particularly adept at meeting unique customer demands for digitally printed corrugated packaging and point-of-purchase displays, catering to both high and low-quantity orders.

The division also provides full structural and graphic design services, serving various product segments such as retail, industrial, and highly engineered packaging. Their solutions encompass a variety of temporary and semi-permanent materials, tailored to meet specific customer needs.

Contractors involved

The facility will be designed and constructed by Briohn Building, a US-based design, build and construction company.

Marketing commentary on Green Bay Packaging

Founded in 1933, GBP is a family-owned, vertically integrated company. It operates corrugated container plants, a folding carton facility, recycled and virgin containerboard mills, pressure-sensitive label roll stock plants, timberlands, a paper slitting operation, and a sawmill facility.

GBP offers a wide array of capabilities, such as structural and graphic computer-aided design (CAD) capabilities, cartons in callipers ranging from .008 to .045, and laminated paperboard including foil, metalised polyester, and susceptor film.

It provides in-house sheeting with various coatings such as UV, varnish, and acrylic coating. Print technology includes up to seven-colour printing in one pass. The company also offers die-cutting, embossing, windowing capabilities both inside and outside, folding and speciality glueing, ensuring a comprehensive range of packaging solutions.

GBP employs more than 4,500 people across 40 facilities in 16 states, with its Great Lakes Packaging Division employing over 80 people.