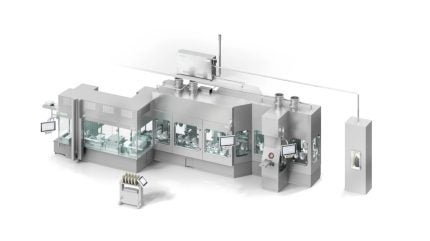

Packaging solutions provider Syntegon has launched its latest MLD Advanced filling machine, tailored for ready-to-use (RTU) nested syringes.

This new offering is designed to meet the escalating demands of pharmaceutical manufacturers for high output coupled with 100% in-process control (IPC), ensuring precise filling. The combination of established technologies enables quick availability and reduced risk.

The MLD Advanced machine can gently process up to 400 syringes per minute. It incorporates automatic bag and tub openers, utilising no-touch transfer to maintain the aseptic integrity of syringes as they move into the filling zone.

Syntegon product manager Markus Burkert said: “Especially with high-value medicines, it is essential that each drop is filled and weighed optimally.

“That’s why we have combined the MLD platform, which was previously used primarily for cartridges and vials, with our technologies for syringe filling.”

Syntegon’s Pharma Handling Unit facilitates the automatic denesting of syringes without glass-to-glass contact, positioning them into the pitch adjustment station. Here, the syringes are aligned with the machine’s pitch before being secured in the transport clips.

Burkert added: “This unique clip system is the first key feature we adopted for syringe applications from the cartridge line.

“The special circulating transport system ensures smooth transportation and is therefore ideal for RTU syringes, as well as vials and cartridges.”

Prior to filling, each empty syringe undergoes a weighing process, utilising 100% IPC. The filling and stoppering sequence follows the established FXS series’ protocols, with the filling needles affixed to the Pharma Handling Unit, allowing for adaptable redosing when necessary.

The company said the IPC system guarantees the accuracy of the filling weight, which is crucial for both minimising product loss and providing verifiable documentation of each container’s weight.

After the insertion of stoppers, either through vacuum or vent tube methods, the containers are conveyed back by the circulating transport system.

The Pharma Handling Unit then carefully repositions the syringes into their nests.

Syntegon’s integrated approach offers customers a streamlined and reliable process for handling their presterilised syringes from a single source.

Earlier this month, Syntegon launched the Pack 103, an upgraded model of its entry-level flow-wrapping machine.