ALPLA Group, a plastic manufacturing company based in Austria, opened an ultra-modern packaging manufacturing facility in Lanseria in the province of Gauteng, South Africa, in October 2022. The new facility serves as the company’s new headquarters for Sub-Saharan Africa.

The site produces bottles, packaging closures and special packaging for the food, personal and home care, chemical, cleaning agent and pharmaceutical sectors, with a capacity of approximately 3.5 billion pieces a year.

The project was developed with an investment of $50m and generated 350 jobs.

The Lanseria facility took over the production activities of five previous plants operated by the company in South Africa, including Harrismith, Isando, Samrand, Denver and Kempton Park. The move was part of a consolidation plan for the company.

ALPLA packaging plant location and details

The state-of-the-art facility is located in Lanseria to the northwest of Johannesburg. It includes 35,000m² of covered space for production, logistics, administration and training and an additional 12,500m² of area for future expansion.

The transfer of production to a single plant streamlined the manufacturing process and improved transport and logistics efficiency.

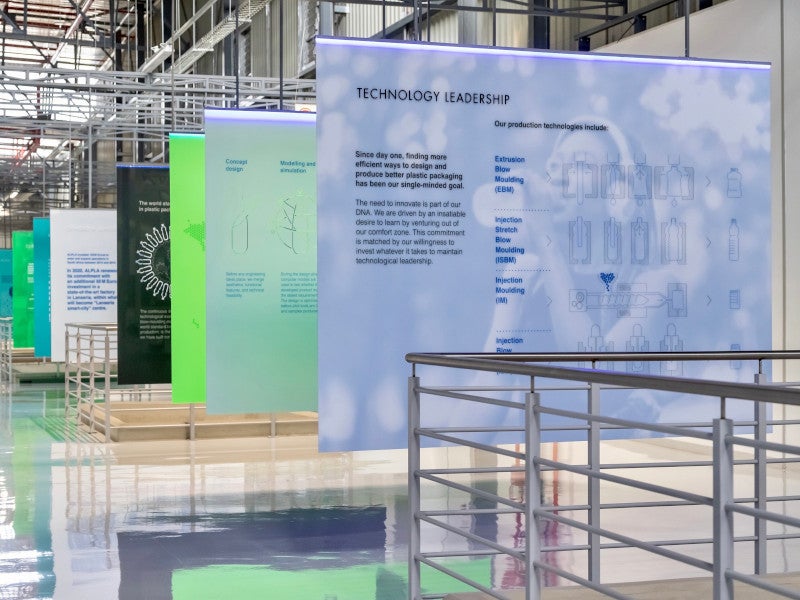

The facility combines all technologies, processes and materials of ALPLA that meet the international quality standards and increase flexibility. It allows the company to undertake production in compliance with the latest globally applicable corporate standards and improve the quality of products while fulfilling customer demands. It has paved the way for the company’s long-term growth in Sub-Saharan Africa.

The Lanseria facility supports the company in conducting its own training for specialists and has established a dual education and apprenticeship programme. The dual system of practical and theoretical training is also in operation at ALPLA’s locations in Germany, Mexico, India, Poland and China.

Sustainability features of the facility

The facility features one of the largest solar installations on a private manufacturing building in South Africa, with 30,000m² of roof area equipped with solar panels.

ALPLA’s product portfolio

ALPLA offers more than 600 different plastic packaging products to meet client’s needs in the fast-moving consumer goods segment. The products, including different types of bottles, jars, canisters, closures, tubes, buckets, capsules and pumps, are supplied to a range of industries, including food, beverage, personal care, home care, chemical, detergent, home care, milk and dairy, oil and lubricants and pharmaceutical.

The company developed a certified coffee capsule, which is made from the Golden Compound green material and can be composted at home. ALPLA, in partnership with Austrian dairy firm Niederosterreichische Molkerei (NOM), developed a milk bottle made up of 100% recycled PET (rPET).

Marketing commentary on ALPLA Group

ALPLA is a packaging manufacturer and producer of rigid plastic packaging for different markets. It manufactures packaging systems, PET bottles, closures and injection-moulded parts and serves customers across the globe.

ALPLA was founded by the Lehner brothers as Alpenplastik Lehner Alwin in Hard, Austria, in 1955. It employs 23,300 people across 190 locations in 46 countries.

ALPLA uses six different technologies, including injection moulding (IM), injection blow moulding (IBM), compression moulding (CM), one-step and two-step injection stretch blow moulding (ISBM) and extrusion blow moulding (EBM). It supplies smaller local and international firms with various plastic packaging solutions.

The company invests approximately €50m ($54.5m) a year in the expansion of its recycling activities globally.

It increased its global footprint and market presence through acquisitions and partnership deals, including opening a site in the tenth of Ramadan City in Egypt, purchasing Boxmore Packaging in Africa, West Bend in the US and Propack in Italy in 2017. The firm also launched the Zero-Pellet-Loss initiative, which reduces the loss of plastic granules during production at its facilities.