Faribault Foods is a well-known food processing/contract packaging company in the US, having started out as a vegetable processing company in 1895, processing corn and peas. The company still packages vegetables and a range of canned ready heat-to-eat meals for a range of customer own-brand labels.

The company introduced new products including a range of stand-up pouch 10% fruit and 100% fruit juice drinks, both own label and for custom-packed brands. This line was part of a company that was taken over by Faribault Foods in 2005 called Soft Pac Industries.

The three pouch-filling lines are based at the Elk River plant in Minnesota, which cost $12m and was constructed in 2001.

Pouch converting at Faribault Foods

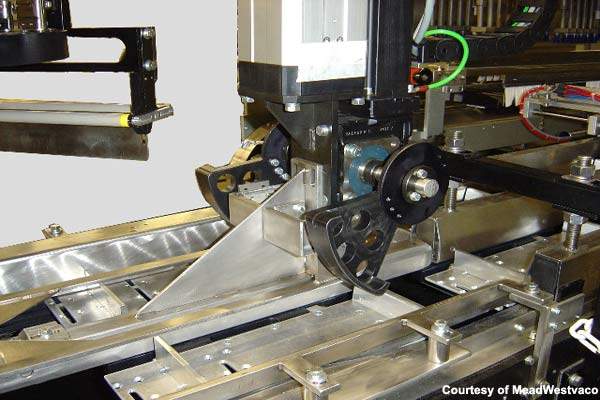

Faribault Foods converts its own pouches for control of quality and inventory. This allows different pouch designs and printings to be carried through quickly and easily according to customer requirements. The stand-up pouches are of a gusseted design and they are produced on two machines supplied by Totani America Inc. The laminated multi-layered extrusion is supplied by Sonoco Products Co and Alcan Packaging. It has a foil centre, and polyester on the outside with polyethylene adhesive layers on the inside. The pouch-making machine has two rolls of film mounted on it; one silver for the back of the pouch and one in eight colours for the fronts. The film runs through the machine in a complicated arrangement so that the gusseted pouch can be formed by heat sealing the front and back onto strips of film for the sides. The completed pouches are printed using Videojet technologies laser printers for lot codes and production date and are then packed in groups of 50 for use on the filling line.

Packing and pouch filling

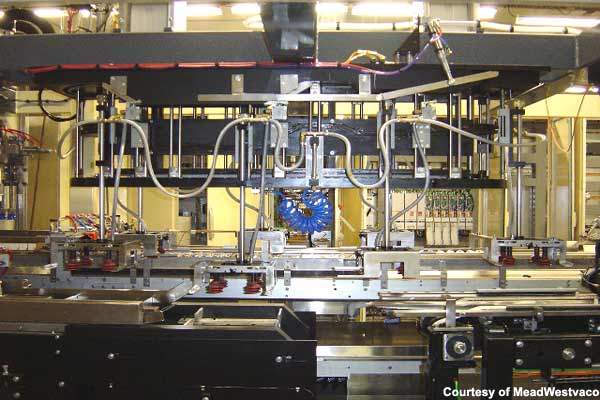

The company’s centre of production for fruit juice pouches at Elk River are three high-speed filling lines that can run at 250 pouches/minute using the standard 200ml stand-up foil-laminated pouch. The process starts with three model TL-AX4 AX4 continuous-motion, horizontal fill/seal machines supplied by Toyo Jidoki Co Ltd.

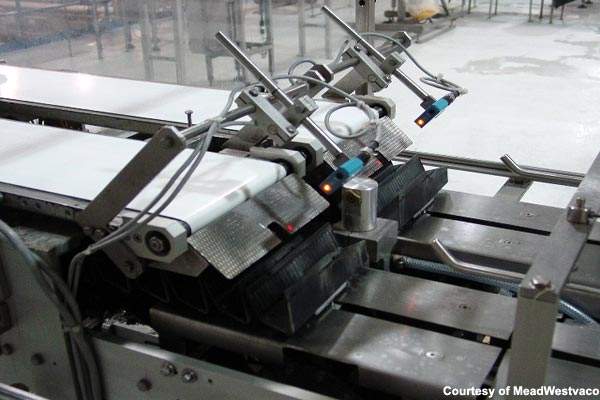

These receive preformed pouches via four in-feed conveyors (supplied by SpanTech LLC). Four pouches at a time are transferred by vacuum cups to grippers, which hold the pouch open at the sides. Grippers then continue the pouch transport. Sensors check if the pouch is positioned ok or if it has been transferred successfully; rejection is carried out by air blowing the offending pouch into a bin. The pouch is carried to a rotary filler (TL-AX4) and filled through one of 18 nozzles under gravity feed from a header tank. Pouches are printed with lot code and production date using a Domino AMJET laser printer and sealed in a two-stage process where two sets of jaws alternately heat seal the pouch and then cool the sealed area.

The set of four pouches are then dropped into a chute to a conveyor and then to a further conveyor and onto a spiral cooler from FMC FoodTech to cool them down from the hot fill temperature. Pouches are transferred to four Dynac accumulators (Hartness) and then to a cartoner (MeadWestvaco) to be packed into tens. A specific requirement of the cartoner was that the pouches were required to pass through the machine at an accurate spacing. To provide this spacing, Faribault set up two automatic feeding machines, supplied by Intellifeed. Cartons are then passed to the SpiraVeyor conveyor (AmbaFlex Inc) and onto a checkweigher (All-Fill Inc). The checkweigher measures and categorises the cartons into three weight segments, which include ‘Under’, ‘Accept’ and ‘Over’. Any pouch that does not meet the specifications is rejected and it exits the checkweigher.

Finally, the cartons go to a Tight Wrap inline shrink bundler (EDL Packaging Engineers Inc) and here up to five cartons are tightly shrink-wrapped together using low-density polyethylene film. The carton bundles are then passed to a palletiser robot from ABB before warehousing and shipping.