As a part of expansion, Inline Plastics built a new plant in McDonough in the state of Georgia, US. It was officially inaugurated in July 2010. The new plant was originally scheduled to open in the third quarter of 2009 but was delayed due to the late delivery of one of the custom-built machines. The distribution began in August 2009 while the production activities at the plant started in December 2009.

The new plant was opened in response to growth in the company’s innovative, environmentally friendly, sustainable food packaging products. The new plant is engaged in manufacturing and distribution of thermoformed plastic food packaging. The new plastic food container facility will facilitate production increase of the US-based plastic food container manufacturer.

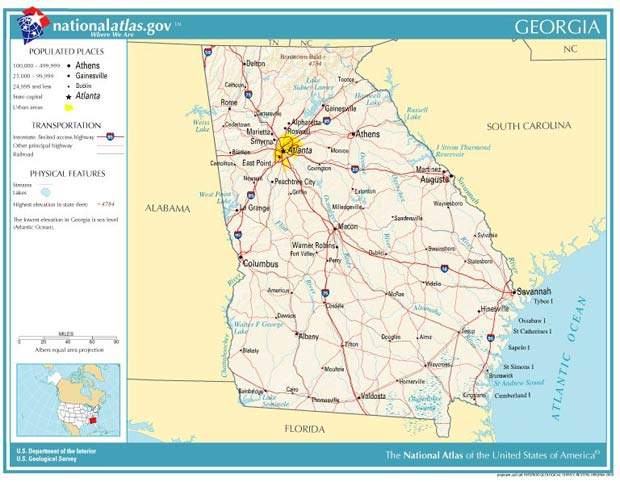

The plant is the company’s first expansion since the opening of a plant and distribution centre in Salt Lake City in 2004. The plant is located at about 35 miles south-east of Atlanta.

The plant is completely owned and operated by Inline Plastics. The capabilities integrated by the facility include manufacturing and warehousing. The investment involved in the project is $3.5m.

Inline Plastics employs between 100 and 120 workers at the plant, in order serve a range of markets. Production start-up in the new facility resulted in the layoff of 30 people from Inline Plastics’s Shelton site and the transfer of ten others to the McDonough plant.

Plant details and equipment

The McDonough plant is constructed on a 58,000ft² area and even includes provisional expansion space. The plant building in McDonough was formerly a 600,000ft² Ford Motor Company parts distribution centre.

The plant includes both new thermoforming equipment and some equipment moved from Shelton.

Container systems

Inline Plastics produces containers for several ready-to-eat foods including baked goods, salads and a variety of grab-and-go foods for the region.

The containers of Inline Plastics include brands such as Valu Pack, EZ Open, Safe-T-Fresh and Crystal Vue. In addition, the company manufactures party platters and salad bowls. The plant also manufactures Safe-T-Fresh products. Safe-T-Fresh is Inline Plastics’s line of clear PET containers used for cut fruit, vegetables and deli applications. These containers are manufactured in 8oz, 12oz and 16oz rectangular sizes in normal as well as containers that can be hanged. The plant also manufactures several other round sizes of Safe-T-Fresh containers ranging from 8oz to 32oz.

The tamper-resistant and tamper-evident containers are manufactured under the brand name Safe-T-Gard and the PETE (a type of clear plastic used for many foods sold in grocery stores) containers for cakes are manufactured under the brand name EZ Open. Containers meeting the needs of high volume processors with automation-friendly design are manufactured under the brand Valu Pack.

Crystal Vue cake containers are manufactured for square shaped cakes, salad bowls and party platters.

Benefits

The new plant has added to the production capacity of Inline Plastics. It has facilitated a reduction in lead times, enabling the customers to increase inventory turnovers and carry lower inventory levels of containers. At the same, the plant has increased flexibility on special orders.

The areas of business served and benefited by the plant include supermarkets, food services, and distribution and processing customers throughout the Southeast of Georgia.

Marketing commentary

Inline Plastics is engaged in the manufacture of thermoformed packaging, supply of crystal clear PET clamshell and two-piece packaging. Headquartered in Shelton, Connecticut, the company also has research and development operation in Milford, Connecticut. Though based in the north-east of the country, it also serves southeastern region and also sees steady growth in the south-eastern region.