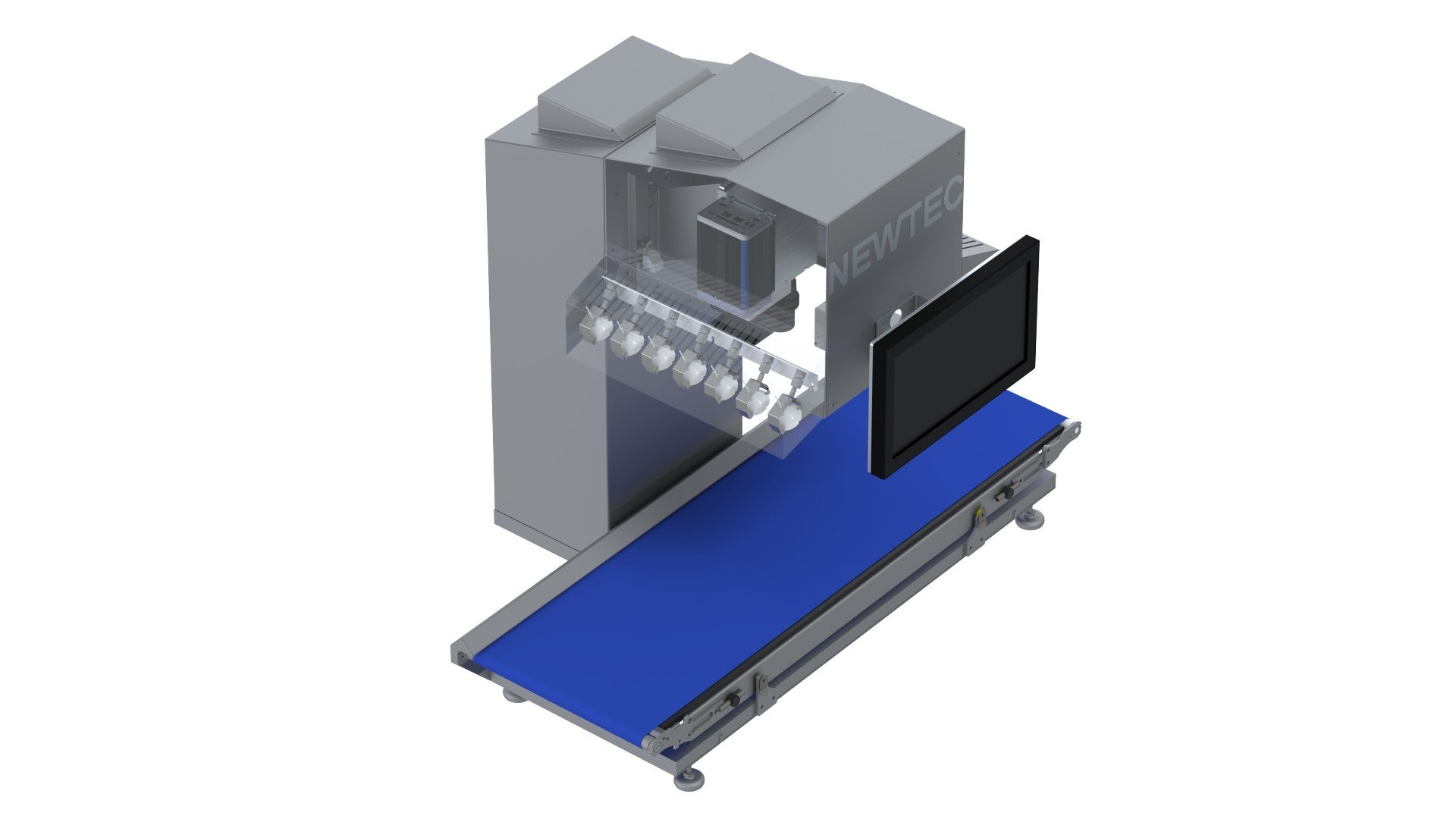

Newtec’s hyperspectral imaging (HSI) camera provides customers with more sorting capabilities and can be used in the packaging industry for material innovation and better quality control.

Newtec recently launched its new HSI camera to give customers more sorting options and access to more and new data, revealing new features for a wide variety of products. These include but are not limited to investigating hidden texts in ancient books, sorting of plastic and quality control of foods.

There are several examples where Newtec faces the challenge of employing the capabilities of the new HSI camera to boost product possibilities and improve sorting options for the food, plastic and packaging industries.

Newtec’s pioneering technology enables the detection of over 300 colours from the visible spectrum all the way to the near-infrared (NIR), hence the term hyperspectral. This is more than an RGB camera with three colours and even the human eye. It divides the light into colours so that the information is more accessible and better managed. With the company’s HSI camera, customers are better able to detect hidden product features that can impact value and quality, as well as health and safety concerns.

Endless applications for the hyperspectral imaging camera

Buteo is a push broom HSI setup developed and assembled in Denmark by Newtec. The hyperspectral capability of this instrument makes it possible to detect information about objects, which would otherwise remain hidden to us. An interesting example comes from the University of Southern Denmark in Odense, where a Buteo is used for retrieving information from hidden texts in antique books.

In medieval times, it was common practice to reuse paper from existing books and old ink, therefore, had to be erased to make room for new content. However, the removal of the old texts was often incomplete, leaving remnants of old ink almost indistinguishable by the human eye. When faced with the problem of finding these hidden texts, the research librarian at SDU, Jakob Povl Holck, turned to Newtec for a solution. Using the Buteo, he was able to scan the medieval books, revealing texts which had remained hidden for centuries, thereby paving the way for the use of HSI in antiquarian studies.

HSI is not only useful for looking at dusty old books, but it also provides important information to the food industry. An example of this would be detecting potato blackhearts, which are internal defects causing the potatoes to develop a black interior, making them unfit for consumption. With the HSI cameras developed by Newtec, it is possible to distinguish potatoes infected with this disease. This technique is non-destructive, which makes it easier to implement thorough quality control in the sorting process and reduces waste.

Hyperspectral technology has also found its way into the packaging, as well as the food and beverage industries, which is in line with Newtec’s vision for transforming the sorting process through research and sustainability. Product safety and sustainability are at the core of Newtec’s values and the capabilities of HSI certainly reflect this.

Another area where hyperspectral technology is being used is in the sorting of different plastics. With the ever-increasing focus on sustainable practices, Newtec provides a technology that can more easily identify types of plastic, which is normally categorised into seven groups, some of which are particularly difficult to trace.

Plastic sorting capabilities for the packaging industry

Newtec’s sorting expertise extends beyond fruits and vegetables to include plastics, among others. Asked by Dansk Affaldsminimering and Plastic and Polymer Engineering group, Aarhus University, to sort polyethylene from polypropylene, Newtec was given a bag with shredded plastic pieces for laboratory analysis.

With the help of Newtec’s cameras and the more challenging spectral analysis, the plastic types were successfully sorted by placing pieces of the plastic on the conveyor belt and camera scanning. Therefore, the HSI camera was able to achieve 100% accuracy and contribute to research about the efficient, non-invasive internal inspection of products such as plastic, potatoes and more. According to Søren Stærke, Optical Engineer at Newtec Engineering A/S, “Many million tonnes of new plastic are created every year around the globe and identifying the different types of polymers can significantly reduce cross-contamination, thereby vastly improving the recycling of the materials. In return, this will reduce the need to make more new plastic.” For the packaging sector, specifically, this technology can have a huge impact on both sustainability practices and better quality control for the kinds of materials used in the packaging industry.

It is interesting to think of the possible advancements in food and material inspection technologies when Newtec’s non-invasive sorting solution is applied to other products such as packaging materials and food.

One can already see the positive results hyperspectral imaging can bring to improving material quality and the quality control process, especially when it comes to choosing the right material for the right product. Newtec is dedicated to research & development specifically aimed at making packaging safer, durable, and sustainable by constantly updating its technologies and trying new methods.