The Extrupet Bottle-to-Bottle Recycling Facility in the Wadeville district of Johannesburg, South Africa, was commissioned in October 2009. The plant produces food-grade rPET resin (USFDA and EU Standards) for the bottle blowing and sheet thermoforming market. It is the only food-grade plastic recycling plant in South Africa.

The plant had an initial production capacity of 425t of rPET resin a month, which has now been increased to 550t after a multi-million rand upgrade. The upgrade was completed recently in January 2011 within a span of three weeks.

The Extrupet facility is undergoing a multi-million rand upgrade to increase its capacity from 450t to 600t a month. The upgrade comes in the wake of an increase in demand for recycled food-grade polyethylene terephthalate (PET) in South Africa.

The plant currently produces blends of 50% rPET and 50% virgin. It also provides customised blending.

Project details

The upgrade has resulted in restricted access to the rPET production areas, which house specialised high-tech equipment. As the rPET is of a higher IV food-grade resin, it goes through an additional step in the recycling process.

Equipment

Extrupet has a fully integrated de-baling, bottle wash, auto-start and grinding system that was designed and built by Italy-based Sorema Plastic Recycling System. The Extrupet facility houses three extruders, two of which were manufactured by Austria’s Erema.

The facility has an in-house laboratory, which is equipped with a gas chromotograph and is capable of testing flakes and chips produced at the plant. Extrupet is the only facility that has its own testing lab and is the first recycler in the world to have been certified to the BRC Standard.

Process

The plant receives the PET material in bales, each weighing an average of 250kg. The bales are opened and sorted into different types of plastic such as pure PET and other non-recyclable plastic like HDPE and bottle caps.

The pure PET bottles are washed and cleaned for further sorting by automatic sorters. The clean bottles are loaded onto the conveyors, in which the bottles pass through a light that identifies the PET that can be used for recycling.

The rejected bottles are automatically blown onto another conveyor. The automatic sorters have 95% accuracy levels and result in over 99% aggregate accuracy.

The bottles are then sent to a manual sorting line, where they are manually checked by workers for purity. These are then grounded into flakes that are specially washed to remove the glue from the bottle labels.

The washed flakes are then bagged for testing before being sent to the food grade rPET plant.

Technology

The washed plastic flakes are left in the vacuum reactor at high temperatures for a stipulated time to remove any volatile matter from the PET flake.

The reactor also reduces the residual moisture and maintains the high intrinsic viscosity (IV) needed for the food-grade plastic.

The flakes are continuously fed into the reactor and then on to the extruder where the PET is made into a melt.

It is then fed into the filter where the residual small-size contamination is separated from the PET melt. This process also enables continuous online IV monitoring and recording of the processed PET melt.

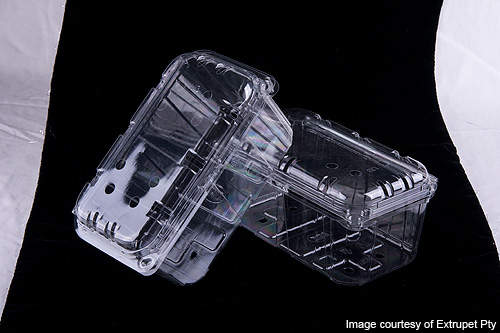

The end product is food-grade, crystallised pellets with high IV levels, which can be reused to produce food-grade containers.

PET Market in South Africa

South Africa will need around 150,000t of PET, 145,000t of which is virgin material. One of the primary reasons for the increased demand of rPET resin is its environmental accreditation. In addition, competitive pricing has brought down the price of rPET to that of virgin PET.

PETCO, Africa’s first self-regulated industry body, plans to recycle 70% of the beverage PET by 2022 in association with Extrupet.

South Africa is also in the process of announcing terms of the Waste Management Act. which was passed in April 2009. The bill is scheduled to be enacted by July 2011.