Mouth African paper and plastic packaging manufacturer Mpact built a state-of-the-art polyethylene terephthalate (PET) recycling plant in Wadeville, Germiston, in the Gauteng province of South Africa.

The R350m ($25.15m) project was developed as part of Mpact’s newly formed operating entity Mpact Polymers, which is a joint venture between Mpact (79%) and the Industrial Development Corporation (IDC) of South Africa (21%).

The plant was officially opened in May 2016. It processes about 29,000t of PET bottles a year to produce 21,000t of raw material called rPET.

Details of the new PET recycling plant

Mpact’s decision to open the new PET recycling plant is based on the growth opportunity of PET recycling in South Africa, a country that uses about 124,000t of PET bottles every year. Approximately 59,700t PET bottles were collected for recycling in South Africa in 2013.

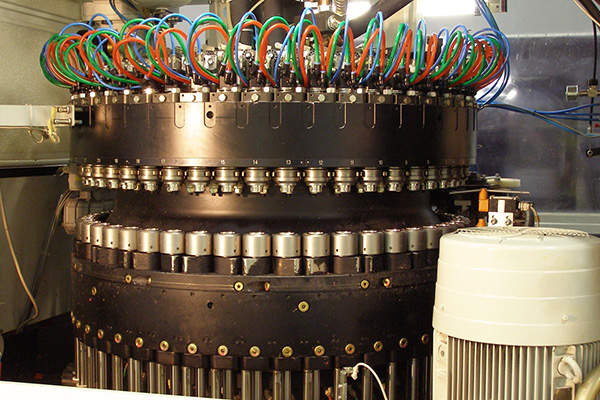

The new PET recycling plant uses advanced technology and equipment to produce bottle-grade recycled PET pellets for use in plastic packaging by processing used PET bottles that otherwise go to landfills.

The company conducted extensive research on the rPET market and technology used in its production, and selected German company Krones as a supplier of equipment for the plant.

Benefits and sustainability of PET recycling plant

The PET recycling plant produces the raw material rPET from used PET bottles, helping to save around 180,000m³ of landfill space every year, which is equal to the size of 75 Olympic swimming pools.

The plant also created 1,000 direct and indirect jobs for operating the plant and collecting the used plastic bottles for recycling.

With this project, Mpact offers its customers an alternative local supply of reliable, high-quality rPET raw material that can be used directly to produce preforms, bottles, jars and food trays. Mpact developed the plan to start the recycling plant in close collaboration with its main customers, including Coca-Cola, Amalgamated Beverage Industries (ABI), SABMiller as well as the South African industry body PETCO, to ensure that the rPET produced from the plant meets international standards.

The PET recycling project slashes the country’s carbon footprint by decreasing the amount of waste going into landfills, as well as helps its customers to reduce their own carbon footprint.

Financing the rPET production plant

IDC of South Africa provided an R210m ($15m) loan for the PET recycling project. The remaining project costs were met through equity.

South Africa’s Department of Trade and Industry (DTI) approved a tax incentive for the recycling project under Section 12I.

Mpact paper and plastic packaging

Formerly known as Mondi Packaging South Africa, Mpact is one of the biggest plastic and paper packaging manufacturers in South Africa. Mpact demerged from Mondi Packaging in 2011 and currently employs 4,000 people in 32 operational sites in South Africa, Namibia, Mozambique and Zimbabwe.

Mpact’s paper business has three main divisions, including paper manufacturing, corrugated packaging and recycling. The company has a strong market presence in plastic packaging in South Africa and offers a wide range of plastic packaging products for sectors, including food, beverage, personal care, pharmaceutical, agricultural, homecare and retail.

Its plastic packaging product range includes bottles and jars, wheelie bins, plastic crates, FMCG containers, styrene and PET trays, fast food containers and clear plastic film.

The company has ventured into PET recycling business with the new PET bottle recycling plant in Germiston, Gauteng.