Netherlands-based global life sciences and materials sciences company, Royal DSM unveiled its plans to construct a new polymerisation plant in October.

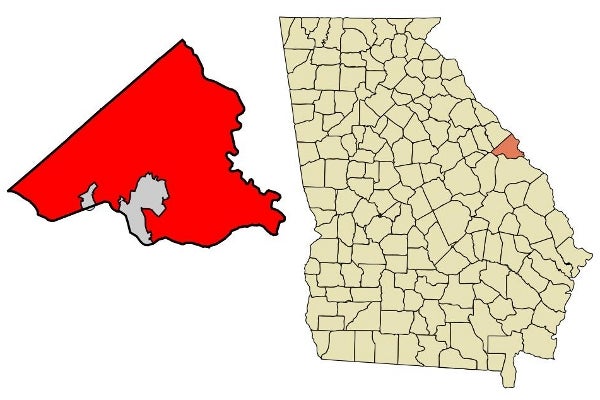

The new facility, to be located in Augusta, Georgia, US, will produce high-viscous polymer for film grades.

Construction of the plant is scheduled to commence in the first quarter of 2015 and commissioning is expected by mid-2016.

Details of the new polymerisation plant for high-viscosity grades

Related content

Royal DSM to build polymerisation plant for film grade polymers

Royal DSM is planning to construct new polymerisation plants in Augusta, Georgia, which will produce high-viscous polymers for film grades.

The new polymerisation plant will be operated by DSM’s Engineering Plastics business. It will be the company’s first polymerisation plant for high-viscosity grades in North America.

DSM operates plants in Europe and Asia for its Engineering Plastics business.

The new plant will manufacture high-viscosity Akulon polyamide 6 polymer for film grades that can be further used in flexible food packaging and other segments.

The facility will be built next to DSM Engineering Plastics’ existing facility on Columbia Nitrogen Drive. The existing facility manufactures patented medium-viscous grades of Akulon and Novamid polyamide 6 polymers, which are used in a variety of components in industries such as electrical and electronics, automotive and consumer goods.

Location advantages of the plastics plant in Georgia, US

Augusta was chosen as the ideal location for the new facility as it offers logistic modalities to the consumers in America, while allowing the company to leverage its existing operations. The location also eases staffing and training activities at the new facility due to its close proximity to DSM’s existing Augusta facility.

The region has a skilled work force, as well as research and development resources, and offers a business-friendly environment for the advanced manufacturing industry.

Benefits of the semi-crystalline structured Akulon polyamide 6

Statistics reveal that almost one-third of food is wasted each year, worldwide.

The main reason attributed to food waste at consumer and retail levels is shortcomings in packaging.

The semi-crystalline structure of Akulon polyamide 6 acts as an excellent barrier against oxygen and aromas, thus significantly increasing the shelf-life of packaged food items, thereby avoiding the environmental and financial costs incurred in food waste management.

The flexible films, based on Akulon material, also offer high mechanical strength and durability, according to Royal DSM.

High-performance plastics manufactured by Royal DSM

Headquartered in Heerlen, Royal DSM offers solutions in the domains of health, nutrition and materials. The company’s product portfolio covers food and dietary supplements, personal care, feed, automotive, paints, electrical and electronics, medical devices, life protection, alternative energy and bio-based materials.

Royal DSM employs about 24,500 people worldwide, with operations in five continents.

Besides Akulon, DSM also manufactures a wide range of specialty high-performance halogen-free engineering plastics such as Novamid 6 and 66 polyamides, Arnitel TPC copolyester, Arnite polybutylene terephthalate (PBT) and polyethylene terephthalate (PET) polyesters.

The company also produces Stanyl high-performance polyamides 46 and 4T, as well as bio-based engineering plastics EcoPaXX polyamide 410 and Arnitel Eco copolyester.