Scientists at Research Laboratories in Sciences Applied to Food (RESALA) and Canadian Irradiation Centre (CIC) have developed biodegradable, ‘active’ packaging materials that can be used in food packaging applications.

For developing the materials, researchers have combined raw renewable materials, such as starch or proteins with nanocellulose, which is a natural polymer that contains nano-sized cellulose fibres, and then irradiated them.

Radiation technology was used to produce the materials, which feature improved durability, biodegradability and water resistance properties than the conventional materials.

The new packaging materials were developed under a five-year project of Austria International Atomic Energy Agency (IAEA) in Austria.

The project, which began in 2013, also included scientists from 14 countries, such as Algeria, Bangladesh, Brazil, Canada, Egypt, Italy and Malaysia.

Research Laboratories in Sciences Applied to Food director Monique Lacroix said: “The race to develop biodegradable packing material or eco-friendly ‘active’ food packaging is gathering momentum.

“Packaging based on natural polymers can help address the challenges of non-biodegradable food wraps and help reduce a major source of environmental pollution.”

Lacroix, who is also a researcher at the Canadian Irradiation Centre (CIC), added: “These polymers are not naturally very sturdy, but when you add nanocellulose and subject it to radiation, the polymers become tough and offer more reliable, sturdy coverage and protection of food.

“Then when we add specific bioactive materials such as essential oils from thyme, the packaging is considered ‘active’ because these additions actively help to extend the shelf life of food and assure food safety.”

According to a 2016 World Economic Forum report, production of plastic has increased over the past 50 years, from 15 million tonnes in 1964 to 311 million tonnes in 2014.

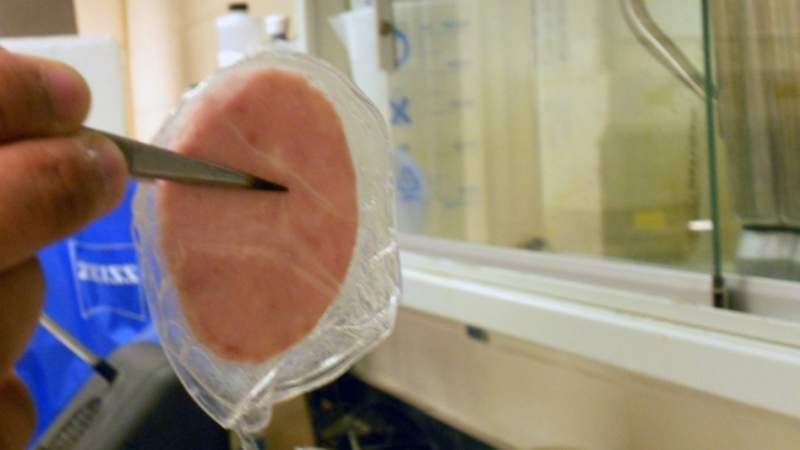

Image: Active packaging for ready to eat meat products based on crosslinked chitosan containing nanocellulose and antimicrobial agents. Photo: courtesy of A. Khan / CIC.