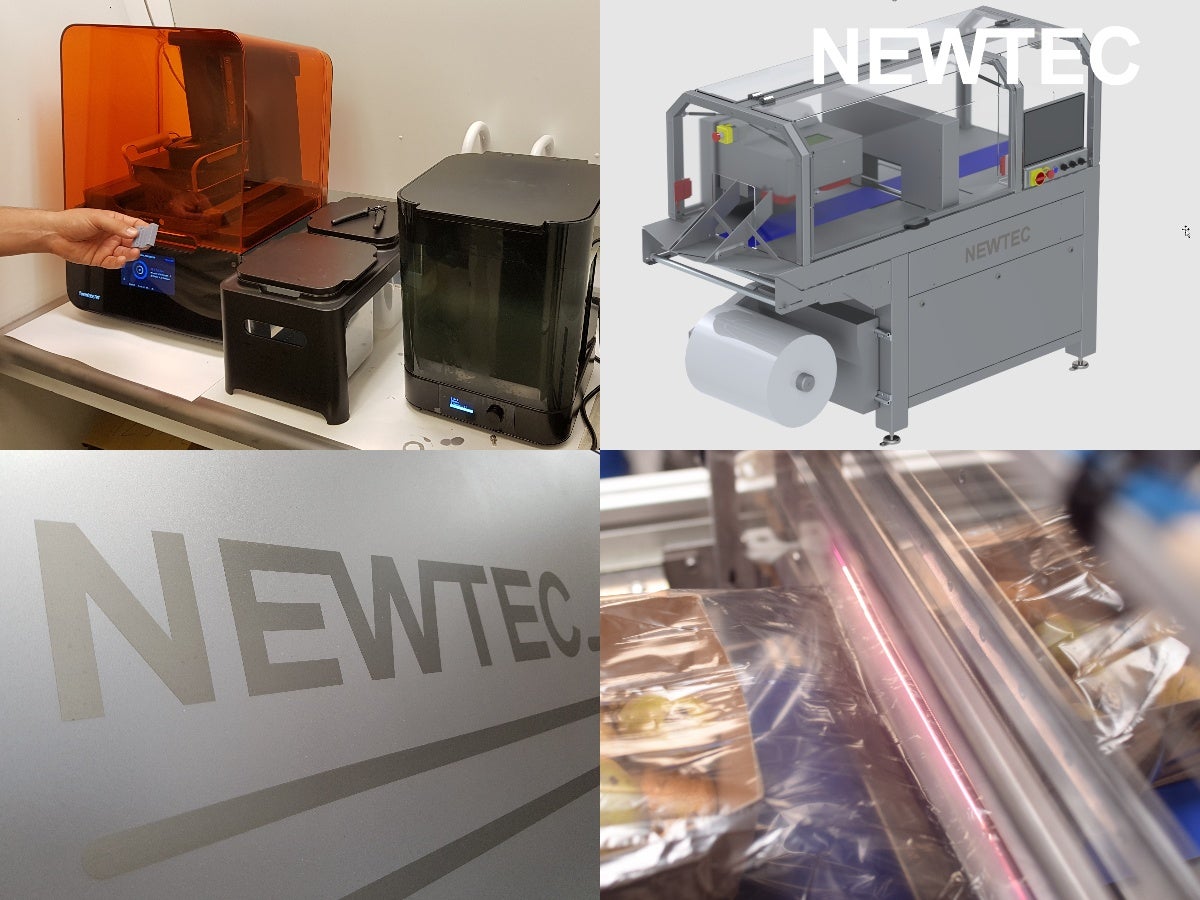

Newtec’s laser FlowPack700 is an ideal solution for clients that require a cost-effective and sustainable technology that is respectful of the high quality of products. With its innovative high-production capacity and reduced plastic consumption, Newtec’s laser wrapper offers a fully automatic service that is easy to use and friendly to the environment.

As a major driving force behind designing and manufacturing the Newtec laser FlowPack700, sustainability is coupled with the high level of automation that the solution provides, making operations smoother and optimal by enhancing production and adjusting to individual customer needs. At a capacity of up to 80 punnets per minute and leveraging the benefits of ultra-thin film, FlowPack700 promises high speed, easy machine use, green operations, and fast return on investment.

All-in-one sustainable laser sealing with ultra-thin film

Newtec’s laser FlowPack700 offers the level of automation clients need to make their production process cheaper, easier and faster. More specifically, the fully automatic machine combines laser sealing and cutting in one operation, simplifying the whole production procedure.

Newtec’s laser sealing machine complies with the EU-2025 plastic initiative, which calls for reduced plastic use and recyclable packaging, and answers customer needs for a green, cost-effective technology that saves time and money, especially after the EU regulations that require companies to pay for their waste.

According to Newtec mechanical design engineers Casper Monrad-Jensen and Andreas Mehl, the laser welding machine saves money and waste as it uses a very thin film and maintains speed and effectiveness. Revolutionising the packaging industry, ultra-thin film allows for the usage of an 8μm of pure polyethylene (PE) material that proves to be a profitable investment as it enables companies to save up to 75%-80% on plastic.

For pack houses looking to cut costs by using ultra-thin film and thereby less plastic, Newtec’s Laser Flowpack700 is a flexible and economical packaging option. Furthermore, it complies with the new EU regulations around plastic.

Offering a large variety of packaging applications, Newtec’s laser FlowPack700 can pack fruits and vegetables in various punnet sizes that can be pre-adjusted and require minimal use of film. “Laser welding is a contact-free technology (no welding jaws) which eliminates inconvenient fused plastics on welding jaws. This greatly reduces the start-up routines of the machine and also greatly reduces film waste in this regard”. Its applications include products that fit the width and height requirements of the machine in the food and packaging industries.

This will help customers boost their sustainability initiatives and benefit from an all-in-one, sealing and cutting machine that also helps them make better use of the materials to reduce waste and save both the environment and money.

Automating production with Newtec’s innovative laser flow wrapper

The technology was developed after careful research and with ease of use in mind, but what is also astonishing is how quickly this innovation was put in place. According to Casper and Andreas, this project started in May 2022 and was launched in Berlin at the exhibition, Fruit Logistica, on 8-10 February 2023. “Instead of traditional manufacturing methods, we saved time and money in the product development phase by using 3D printed parts. With 3D printing, individual parts can be quickly and easily produced on demand. This also reduces waste and cuts down on production costs and lead times”.

The mechanical design engineers worked in close collaboration with Henrik Andersen, who is the head of the Newtec RD Department and software developer, as well as laser expert Dr Victor Petrunin, researcher, who works in Newtec’s in-house laboratory.

All tests having been carried out in-house by top-level engineers and researchers, clients can be reassured in experiencing the high quality of the technology, as well as the innovation that it brings to the market. The meticulousness of design and manufacturing attests to the level of expertise and knowledge the Newtec engineers use to make the laser wrapper a reality.

Cost-savings, automation and easiness in the wrapping functioning are three main qualities that Newtec offers. As Casper and Andreas point out, complex setups take up time and generate the need to train staff so that production performance runs smoothly and effectively. With Newtec’s machine, there is no need for time-consuming start-up adjustments and operations that may complicate production.

This level of automation is in line with all Newtec products, which have been involved in a variety of projects and revolutionised the packaging industry. Minimising the use of plastic and packaging waste as well as making laser sealing and cutting easier, faster and much cheaper comprise the main advantages of Newtec’s laser FlowPack700, which offers an all-in-one solution for clients who want to save money, go greener and boost their performance.