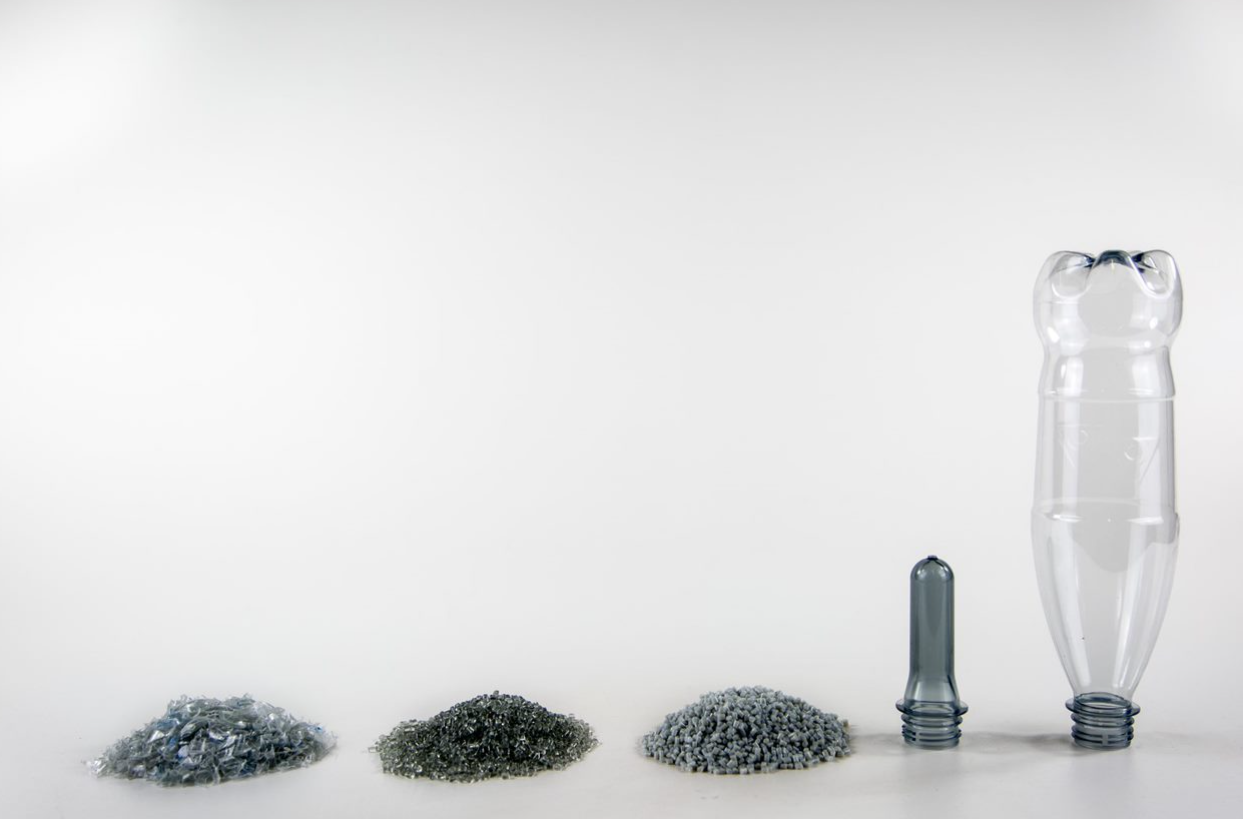

Sidel aims to facilitate a smooth and efficient market switch to recycled PET by establishing a ‘no fear’ one-stop shop for rPET called ‘RePETable’.

These service solutions will enable customers to adopt up to 100% rPET without impacting bottle production.

The RePETable offer is designed to extend virgin PET benefits to rPET and achieve consistent production performance and bottle quality.

RePETable has been designed for customers to pick and choose services that best suit their specific needs. It is additional to Sidel’s packaging optimisation services for lighter bottle weight, helping customers make a cost-efficient transition to recycled PET.

Sidel packaging innovation experts continue developing advanced knowledge about recycled PET resin and solutions for efficient bottle production by leveraging its small-scale recycling pilot line in France.

Sidel packaging and moulds project manager Jérôme Neveu comments: “To reach the same level of performance as virgin PET, rPET bottle production process needs to be adapted to suit the resin used. We are continuing to innovate and find more breakthrough solutions for rPET bottle production.”

Sidel packaging expert global Naima Boutroy adds: “While PET is already fully compliant with the circular economy compared to other plastic packaging materials, combining lightweight and recycled PET is the fastest way to reach carbon neutrality.”

In May, the company launched Bottle Switch, a robotised mould replacement for the food packaging industry.