With its global headquarters located in Concord, Ohio, Ranpak has been a producer of sustainable paper packaging with a focus on innovative solutions since 1972. Ranpak has been recognized by the 2024 Packaging Gateway Excellence Awards in the Innovation, Product Launches, and Environmental categories.

These categories represent key areas of focus for Ranpak as they continue to introduce new products across its protective packaging and automated solutions portfolio without losing sight of environmental impact and recyclability.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The Packaging Gateway Excellence Awards celebrate the greatest achievements and innovations in the beverages industry.

Powered by GlobalData’s business intelligence, the Awards recognize the people and companies that are driving change in the industry.

“We are proud to receive this recognition from the Packaging Gateway Excellence Awards. Innovation has been a tradition within our company since our founding: it’s as core to our identity as our commitment to sustainability. Expanding our solutions into areas like cold chain shipping and end-of-line packaging automation raises the bar on packaging standards now and in the future.”

– Omar Asali, Ranpak’s Chairman & CEO

Innovating to optimize end-of-line packaging

The Cut’it!™ EVO Multi-Lid automated height reduction solution allows a single packaging line to minimize package void and apply up to four distinctly branded lids, which helps operators save on shipping cost, improve throughput, and can often result in higher package quality. The importance of right-sized packaging extends beyond customer satisfaction and cost savings through controlling dimensional weight. Upcoming regulations, including the European Packaging Directive mandate for 50% maximum void in packaging by 2030, underline the need for solutions to help operators achieve compliance.

The ability to accommodate up to four unique lids allows for customization that helps facilitate more efficient packaging processes and improves the competitiveness of 3PL providers by accommodating multiple brands on one line. Designed as a modular and scalable solution, lines equipped with a Cut’it!™ EVO Multi-Lid system can easily scale with seasonal peaks and accommodate long-term business growth.

Finally, by combining height-reduction with optimized box footprints, the solution produces right-sized packaging that is designed with the customer in mind. Each branded lid features an easy-to-open tear strip, while the box itself is strong and tamper-evident, minimizing damage during shipping and reducing returns.

Supporting the circular economy with paper packaging solutions

Ranpak continues to release new products to address the needs of its customers and distributor partners. The naturemailer™ padded mailer solution is a fully curbside recyclable mailer system that uses honeycomb paper insulation to protect products in transit. Ranpak recently launched the naturemailer™ line as an eco-friendly alternative to legacy solutions in the market, aligning the product announcement with the annual Earth Day theme of “Planet vs. Plastics,” directly addressing the global challenge of plastic waste. Because of their paper-based construction, these mailers are able to be recycled along with household paper waste, fitting into a circular economy where packaging materials can be used and reused beyond a single cycle of consumption.

These flexible mailers are available in multiple sizes and offer custom printing options, accommodating a variety of industry needs with design features that help simplify the packing and opening process. Ideally suited for applications in e-commerce and healthcare, the paper solution is meant to facilitate easy recycling at end of life while supporting cost savings and productivity for businesses.

Bringing the recyclability of paper into the cold chain

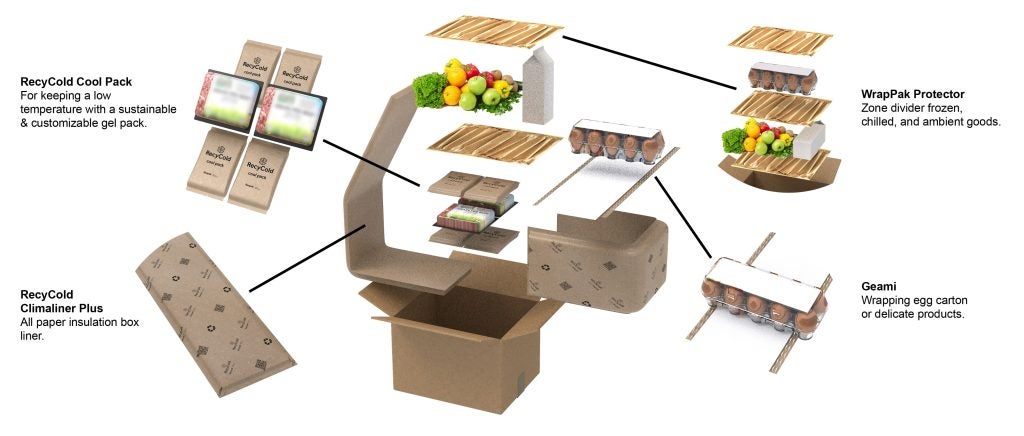

Ranpak’s climaliner plus™ cold chain liner solution helps to solve the need for longer lasting cold chain solutions that can still be fully recycled at their end of life. Engineered to provide up to 72 hours of thermal protection in a 100% paper-based curbside recyclable format, these cold chain liners can replace less sustainable packaging materials like EPS foam while keeping goods cool and protected over longer, colder journeys.

Like the original climaliner™, Ranpak’s climaliner plus™ liners are secondary food contact safe and able to support custom printing for private labels, which boosts branding while maintaining sustainability. The flat profile of these liners helps optimize the packaging environment, as they are able to be stored with less space required when compared to pre-built coolers. The liners work in tandem with Ranpak’s RecyCold™ portfolio including RecyCold® cool packs, which contain a bio-based gel to further minimize the use of plastics and chemicals in cold chain shipping.

Company Profile

Founded in 1972, Ranpak’s goal was to create the first environmentally responsible system to protect products during shipment. The development and improvement of materials, systems and total solution concepts have earned Ranpak a reputation as an innovative leader in e-commerce and industrial supply chain solutions. Ranpak is headquartered in Concord Township, Ohio and has approximately 830 employees.

Contact Details

Megan Wintersteen

VP Digital & Corp Marketing

E-mail: Press@ranpak.com

Links