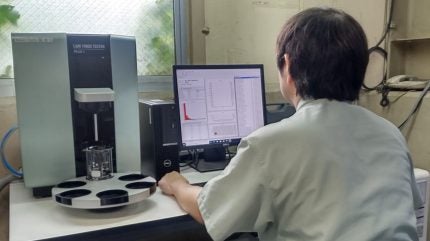

Japanese paper manufacturer Kami Shoji has turned to ABB’s automated testing solution, L&W Fiber Tester Plus, to enhance its cellulose nanofibre (CNF) paper production.

The device offers rapid and precise fibre quality measurement, aiding in the optimisation of defibration processes.

Defibration, the process of separating wood fibres for papermaking, is a critical step in CNF production.

Kami Shoji’s innovative approach to CNF production is more cost-effective than traditional chemical methods.

By using a specialised press, it achieves faster dewatering, resulting in a product with comparable strength and environmental resistance.

Kami Shoji’s CNF paper also exhibits unique properties, including excellent elastic deformation and superior strength.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThese characteristics make it ideal for structural, insulation, and soundproofing applications.

The efficiency of mechanical defibration CNF production relies heavily on accurate fibre inspection.

ABB’s L&W Fiber Tester Plus offers automated fibre morphology analysis, enabling the observation of thousands of fibres within minutes.

“Kami Shoji has used L&W Fiber Tester Plus extensively for the criteria of fibre conditions required for research and development of CNF paper,” said Shosaku Kashiwada, PhD, acting general manager of Development Plan Section, Kami Shoji.

“We are very satisfied with the device, which provides extremely valuable measurement results during CNF research.”

“ABB L&W Fiber Tester Plus is already being used by major Japanese public institutions in Shizuoka, Gifu and Kochi, where many pulp and paper companies are situated, thanks to its proven ability to quickly and accurately extract valuable raw paper defibration data to inform advanced research,” added Hiromichi Yoda, local division manager, Process Industries at ABB Japan.

“ABB is positive about extending collaboration with specialist paper producer Kami Shoji, who will continue to benefit from optimised operation conditions at its facilities, leading to improved quality control, productivity and stable production.”

ABB’s L&W Fiber Tester Plus offers a comprehensive range of measurements, including fibre length, width, microfibrils, and coarseness.

Additional features such as software modules for crill and vessel cells further enhance its capabilities.

By leveraging ABB’s automated testing solution, Kami Shoji is positioned to improve its CNF paper manufacturing operations.