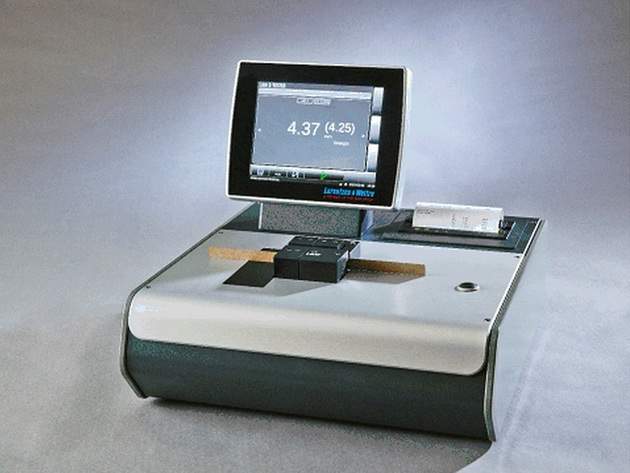

Switzerland-based technology group ABB has introduced a new L&W S-Tester, which helps determine the quality of fluting medium in corrugated packaging material.

Expanding ABB’s laboratory assessment portfolio, the newly developed tester is designed to help paper producers improve quality and reduce costs.

The L&W S-Tester is said to offer quick and accurate feedback, as well as perform automated S-tests using L&W Autoline, a paper quality measurement system.

The tester also helps to reduce energy consumption by eliminating over-refining, optimises the use of starch additives, and assists in the production of a uniform paper product.

Developed by the Cepi Container Board (CCB), the S-test is said to provide an easier measurement method than the Concora Medium Test (CMT), which involves a time-consuming crushing process for corrugated materials.

Furthermore, the new S-test works well with the compressive yield strength potential of fluting medium in a CMT test, and produces better strength results when predicting the ability of fluting medium to keep liners apart.

ABB pulp and paper products global product manager Thomas Fürst said: “This test method, developed by a group of industry partners, is now offered as a fully-supported product only by ABB.”

The company currently provides electrification products, robotics and motion as well as industrial automation and power grids for transport and infrastructure and other sectors worldwide.

Image: ABB’s new L&W S-Tester. Photo: courtesy of ABB.