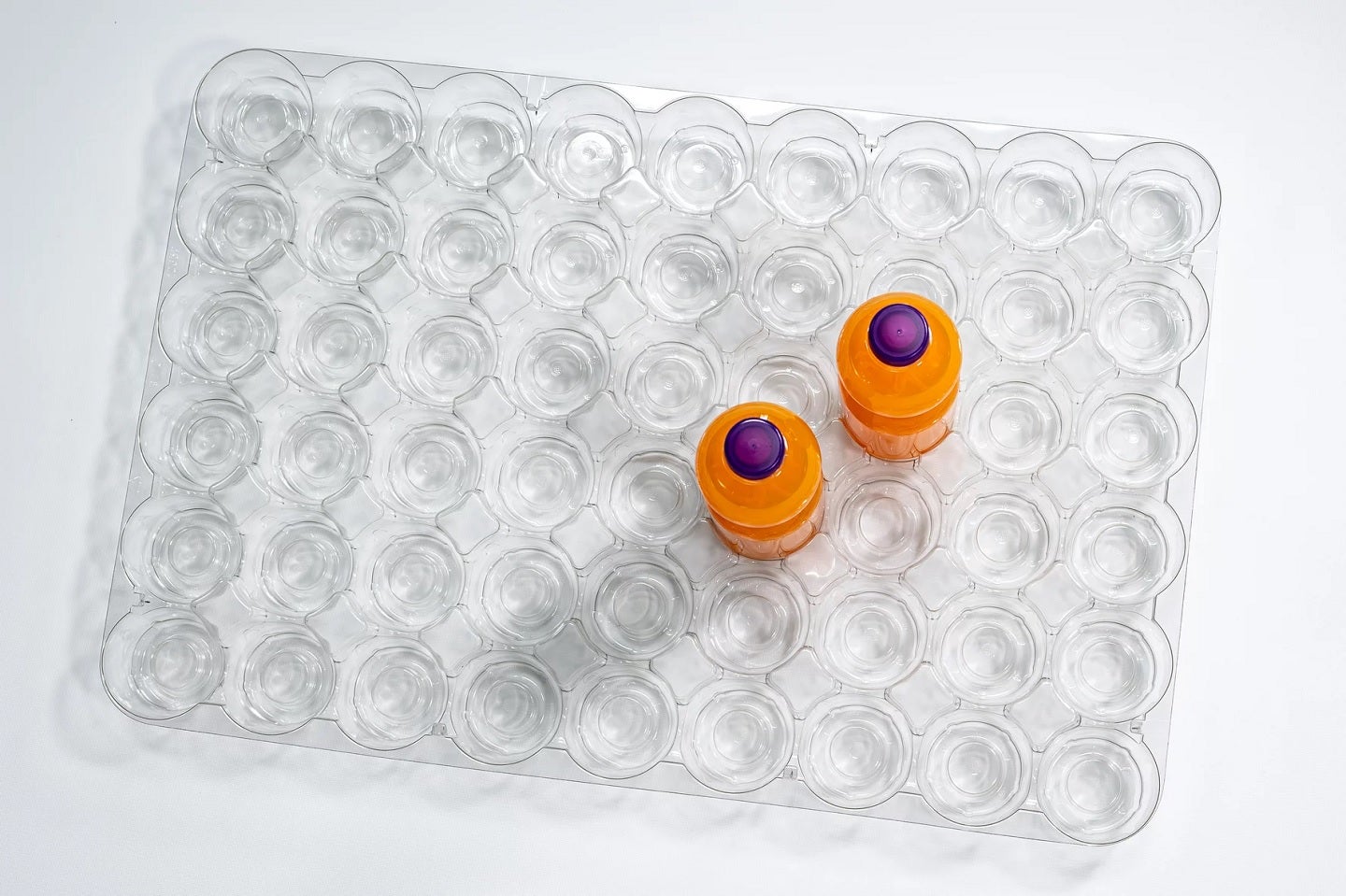

Greiner Packaging has produced trays made from 70% recycled polyethylene terephthalate (r-PET) for Austrian beverage company Rauch Fruchtsäfte.

Greiner is utilising material from ‘yellow bags’ to produce these sustainable beverage trays.

During the course of the project, it was demonstrated that r-PET flakes could be generated from post-consumer material through pre- and post-sorting, followed by shredding and washing.

The process involves creating a PET film (made from 70% recycled material) from these flakes. Later, the company’s business unit, Greiner Assistec, thermoforms this film into r-PET trays.

The r-PET flakes come from input materials other than PET beverage bottles such as cups, tubs, and trays.

In the plastics industry, sustainable packaging is mainly produced by recycling PET bottles into r-PET flakes.

The potential to recycle additional PET packaging from yellow bags is currently underutilised, according to Greiner.

Greiner Recycling director Peter Fessl said: “By expanding a year ago, we sent a clear signal and underscored that we believe in the potential of r-PET for a sustainable future of the packaging industry.

“Even then, it was our clear goal to drive recycling streams away from [virgin PET] bottles. The project together with Rauch Fruchtsäfte is just one step on this path, to be followed by many more.”

The beverage company is already using bottles made from 100% r-PET in its operations, as part of its sustainable efforts.

Rauch purchasing manager Hanno Mandl added: “As a beverage manufacturer, we are of course particularly keen to ensure that high-quality r-PET from the bottle flow is also available for the production of new r-PET bottles and that alternative forms of packaging are used for the manufacture of other products.”