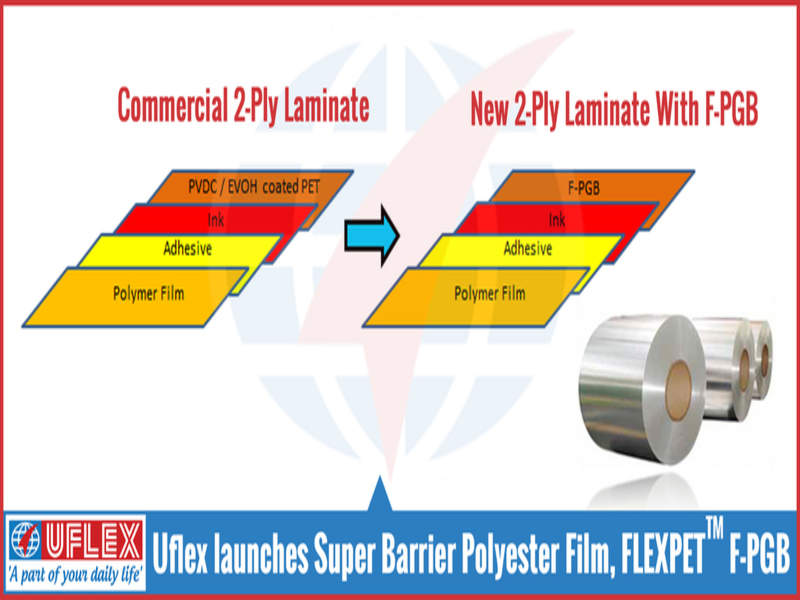

Indian flexible packaging company Uflex has unveiled FLEXPET F-PGB-12, a new polyester film that reduces oxygen transmission, as well as exhibits optical properties and transparency.

The new 12μm bi-axially oriented polyethylene terephthalate (BOPET) film features a specially modified surface treatment on one side to reduce the transmission of oxygen.

The other side of the film can be corona-treated or left untreated, depending on converter requirements.

Uflex Technical Service and New Product Development (Films) assistant general manager Sharma said: “This film offers a clear cost advantage to the converters over other PVDC / EVOH-coated / co-extruded films and is widely used in the packaging for pet foods; roasted coffee and other oxygen and barrier-sensitive food products.

“There is a huge demand for this cost-effective speciality BOPET film and we are getting a good number of business enquiries.”

FLEXPET F-PGB-12 has an oxygen transmission rate (OTR) of less than 6cm³ / m² / day at 23°C and 0% relative humidity (RH).

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataUflex Technical and New Product Development (Films) president Pramod Sirsamkar said: “In a typical two-ply laminate our latest film can serve as a superior oxygen barrier while the sealant layer can act as a great barrier to moisture.

“This is the simplest cross section that one can think of keeping the converting costs to a bare minimum without compromising upon the performance of the laminate.”

The film does not require any coating or co-extrusion of polyvinylidene chloride (PVDC) or ethylene vinyl alcohol (EVOH) to improve its barrier properties.

FLEXPET F-PGB-12 offers superior machinability and handling properties due to its high tensile strength at break (TSB) and high barrier to gas.

Image: The new bi-axially oriented polyethylene terephthalate film has a specially modified surface treatment on one side. Photo: courtesy of UFLEX.