Corrugated paper and cardboard packaging producer Kinnareds Well has partnered with Rockwell Automation and Hax Technologies for the upgrade of its assembly line’s human-machine interface (HMI).

The Swedish packaging company selected Rockwell Automation’s Allen-Bradley OptixPanel Standard Graphic Terminal for its apparent reliability, ease of use, and versatility, integrating seamlessly with FactoryTalk software.

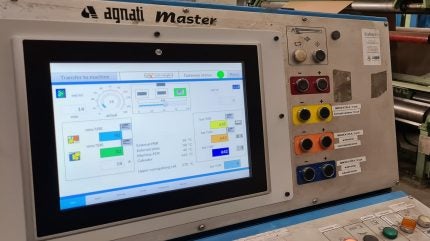

The new HMI displays offer high-resolution graphics and an intuitive, configurable interface.

Engineers from Hax Technologies were able to quickly connect and configure OptixPanel, significantly reducing downtime for the assembly line.

The terminal’s secure remote-access features allowed much of the configuration to be completed off site, with Hax Technologies also providing remote support through a long-term service contract.

Kinnareds utilised the panel’s built-in web server to give staff remote HMI access from other locations, eliminating the need for additional panels.

Hax Technologies automation manager and Kinnareds upgrade project team lead Peter Nilsson said: “The combination of the OptixPanel Standard Graphic Terminal’s ease of configuration, its versatility and the advanced remote-access features meant it was both easy to configure and easy to get the best possible performance from the assembly line.”

Kinnareds supplies its products to retailers and manufacturers across Europe.

Kinnareds CEO Peter Syrén said: “The combination of the easy-to-use interface and the advanced remote-access features have helped to improve the operator experience and to maximise productivity.”