Researchers from North Carolina (NC) State University have found that biopolymers obtained from the ocean can be used to replace synthetic, petroleum-based plastic films.

Authors of the research paper, published in the Cell Reports Physical Science journal, include NC State Chemical and Biomolecular Engineering researcher S Frank, Orlin Velev, distinguished Professor Doris Culberson, and NC State PhD graduate and first author of the paper, Yosra Kotb.

The research showed that materials obtained from crustaceans and seaweed had enhanced structure and could serve as a sustainable alternative to replace petroleum-based plastic films.

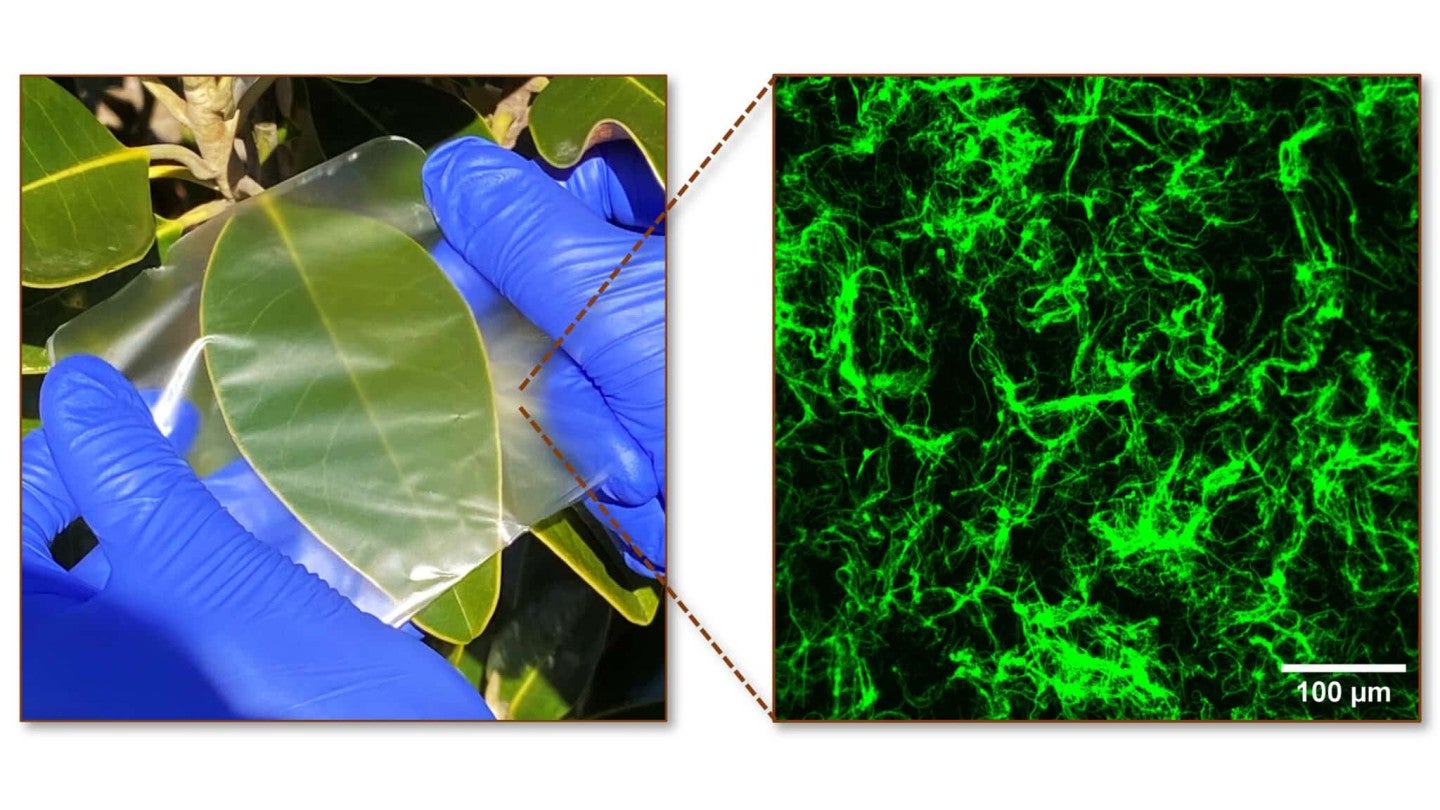

Chitosan, a biopolymer that makes crab shells durable, when combined with another biopolymer derived from seaweed (agarose), can create a new biopolymer composite film that offers high strength.

The films are biodegradable, transparent, water-resistant, and have various antibacterial properties.

The findings also highlighted that biopolymer composites are nearly four times stronger than sole agarose films and can resist the E. coli bacterium.

The NC State team can now further support the development of sustainable packaging films for food and consumer goods.

However, according to Velev, combining chitosan and agarose may not be enough, as previous efforts to manufacture similar types of mixtures only reported improvements in properties and eventually created a ‘gritty film’, which may not have enough strength.

Velev is now working with his team using a different approach to reinforce agarose films with fibrillated colloidal scale chitosan-made material, referred to as ‘soft dendritic colloids’.

Kotb said: “It is challenging to modify natural polymers chemically, but we can alter their morphology and use them as composites.

“We use chitosan dendritic particles to reinforce agarose matrix because of compatibility of both materials leading to good mechanical properties; chitosan particles also have an opposite charge to agarose.

“When mixed, these charges are neutralised so the resulting materials also become more resistant to water.”

The team has filed a patent application for this biopolymer composite film solution and its process of creation.