Researchers from Purdue University in the US have created a new large-scale manufacturing process for grocery store food packaging.

The manufacturing process developed by the research team uses cellulose nanocrystals (CNCs), which are alternative renewable raw materials obtained from natural sources, such as wood and plants, as advanced barrier coatings for food packaging.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

CNCs are being projected as ‘excellent’ components for advanced food packaging on the basis of their properties, including nontoxicity, biodegradability, high specific strength, high thermal conductivity and optical transparency.

Purdue University School of Materials Engineering professor Jeffrey Youngblood said: “The challenge for the food packaging industry is to create a recyclable and sustainable barrier material that is low-cost. Our innovation using CNC coatings is transparent, nontoxic and sustainable.”

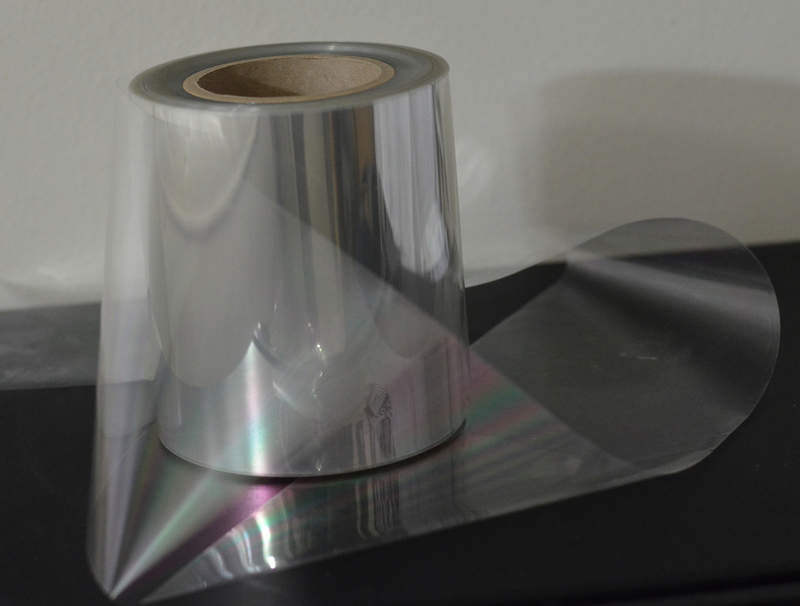

According to the researchers, the newly developed method is a roll-to-roll manufacturing process that uses waterborne polymer systems and offers scalability.

Furthermore, the highly crystalline nature of CNCs and their ability to be easily dispersed in water allows manufacturers to control the structure to eliminate free volume.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThis results in retaining only the properties that are needed for the barrier material.

Youngblood added: “Our unique process uses the power of natural nanotechnology and allows a much higher density and packing coating that reduces diffusion pathways and drastically improves oxygen, carbon dioxide and water vapour permeability.

“In essence, we get properties similar to common packaging such as ethylene-vinyl alcohol polymer, but with more sustainable results.”

Food packaging manufacturers can also leverage the Purdue technology’s optical, thermal and mechanical properties to ensure freshness of grocery products.