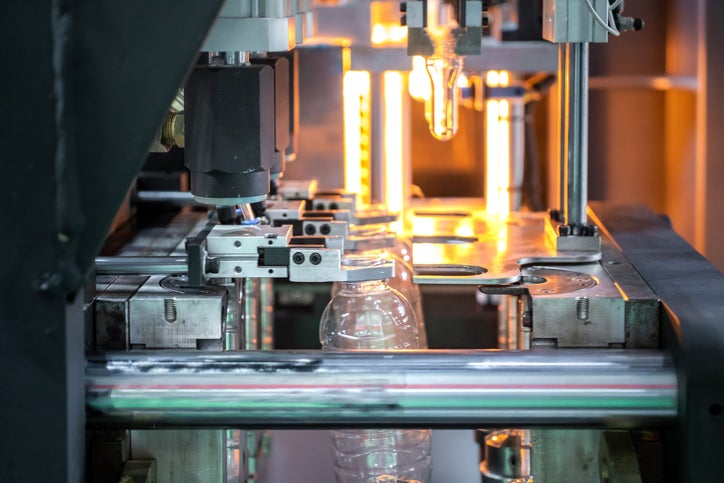

In its latest offer in equipment for liquid food packaging, Sidel has launched Bottle Switch, a robotised mould replacement carried out by a double mould holder robot.

The equipment can be applied to gravimetric preform feeders, ovens, and blowing wheels to support switching in preform neck finishes and bottle shapes.

It reportedly provides 98% efficiency and shortened changeover duration with the possibility to efficiently select and apply the right equipment process and configuration for every stock keeping unit (SKU).

The SKU specifications are stored in the process recipes. They are all accessible through human machine interfaces to save, centralise, and repeat processes.

Sidel states that compared to a standard manual changeover, Bottle Switch’s changeover time can be reduced by 75% and has the potential to produce up to 13.2m bottles per year.

The company’s blowing machines feature motors to support the automatic mechanical element positioning for the gravimetric preform feeder’s infeed rails. This also assists the oven’s heating modules and cooling shields.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataLast month, Sidel aided the launch of an aseptic production line in Ghana for the cocoa processor Niche Cocoa Industry to install ventures into milk-based products with PET.

Sidelwas founded in 1965 and is a subsidiary of the global packaging company Tetra Pak.