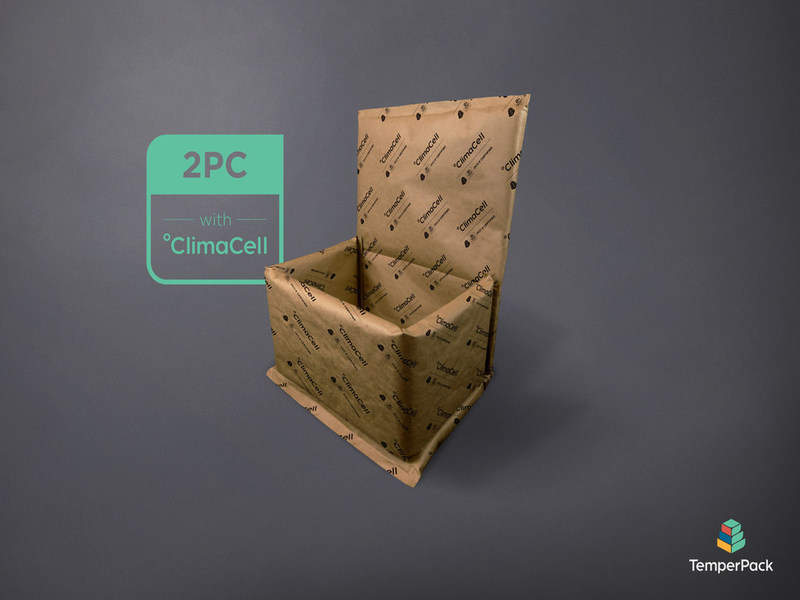

Sustainable packaging firm TemperPack has launched a new paper-based recyclable insulator packaging solution in order to create fully curbside, recyclable box and bag liners for the transportation of perishable goods.

The paper-based insulator, which is called ClimaCell, has been developed as an alternative to common insulating materials such as EPS foam coolers.

The product also allows for protection of temperature-sensitive shipments for up to 80 hours.

Certified to the standards of the Fibre Box Association and the American Forest & Paper Association, ClimaCell helps reduce packaging waste.

TemperPack co-CEO James McGoff said: “When a package shows up at the door, almost everyone knows what to do with the cardboard box afterwards – throw it in the blue bin. In fact, people get this right 93% of the time.

“With the massive growth in e-commerce fuelled perishables like food and medicine, we wanted to introduce ‘guilt-free’ insulation that was just as easy to recycle as the cardboard box it came in.”

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe company said it intends to cut down plastic pollution by switching to sustainable and recyclable solutions.

It also said that the use of foamed plastic in the manufacturing of traditional insulation materials makes them incompatible with curbside recycling.

TemperPack focused on maximising thermal performance and moisture resistance while keeping weight and storage space to a minimum. The insulator will also feature fully customised graphics and label.