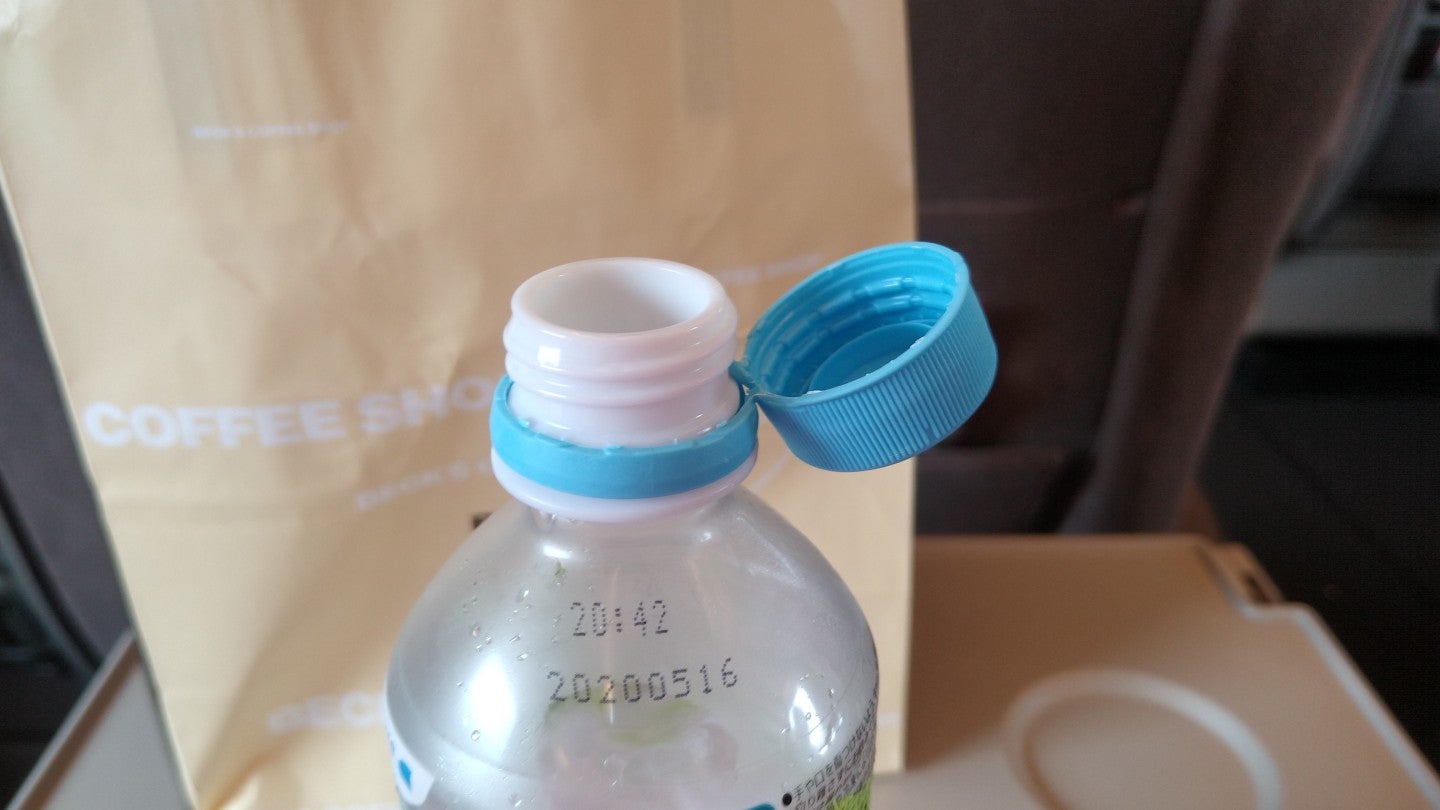

France-based polymer manufacturer TotalEnergies has commercially launched its new high-density polyethylene (HDPE) resin that can be used for tethered cap applications.

The new solution is named HDPE 20HD07 and features improved mechanical and organoleptic properties.

It uses less material than its market reference while providing a similar technical cap performance.

The HDPE resin is capable of minimising the overall carbon footprint of its end applications on caps for beverage bottles or in cosmetic packs.

The resin has been designed for monomaterial polyethylene packaging solutions to further enhance recovery, sorting and recycling processes in the industry while contributing to a circular economy.

The company said that this resin is most suited for food-grade packaging and adheres to all the requirements of the caps and closures market.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataAdditionally, it is in compliance with the EU Directive 2019/904, which focuses on reducing the impact of plastic products on the environment.

TotalEnergies said it is displaying the HDPE 20HD07 during the two-day AMI Plastic Closure Innovations conference, which is being conducted in Barcelona, Spain, between 14 and 15 June.

TotalEnergies Polymers Europe & Orient vice-president Olivier Greiner said: “TotalEnergies is fully committed to improving the environmental impact of its products.

“Applying eco-design principles in our development process allows us to push downgauging possibilities further, while maintaining high performance and enhancing recyclability, in line with our ambition to produce 30% circular polymers by 2030.”

The company specialises in developing and commercialising polymers such as polypropylene and polystyrene, as well as their recycled equivalents and biopolymers, to integrate them all together in the plastics manufacturing process.