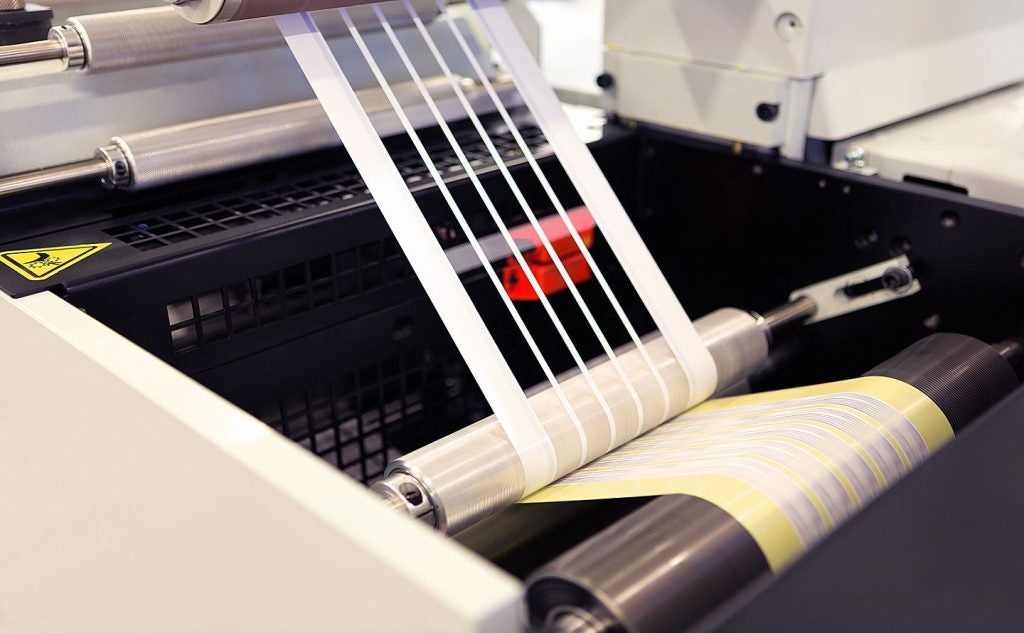

UK-based Baker Labels has announced the installation of a new HP Indigo 6k press to improve its production operations.

The acquisition represents an enhancement to the HP Indigo WS6800, which was acquired in 2014.

To accommodate the incoming larger press with ILP and remove the outgoing HP Indigo, a significant rearrangement of the digital area was necessary in preparation for installation.

For this purpose, the teams from both the entities worked for several days to minimise production disruption.

Leveraging HP Indigo Spot Master and other automated colour calibrations, the new press offers faster time-to-colour and an automated colour-matching process that helps maintain colour consistency and repeatability.

The press offers up to four times quicker colour calibration while printing based on a higher frequency spectrophotometer.

It also features an integrated variable data engine and web-based user interface that helps access DFE from any computer on the network without the requirement of to install multiple ‘clients’.

Baker Labels managing director Steve Baker said: “This latest HP Indigo 6k press with ILP was a natural progression as we needed to update our original 6800.

“It’s our first to include an in-line primer unit – we currently coat our materials offline, so this gives us a few more options. We have a policy of ensuring our staff have the best equipment to produce top quality work with the least number of issues.”

The company’s digital department currently has three HP Indigo presses and two Screen Inkjets. BakPac, the company’s flexible packaging division, also houses an HP indigo 20k press.

A Nilpeter FB3 flexographic printer completes the reel-to-reel label press lineup, stated the company.