German company circular logistics has partnered with packaging business rhinopaq to design and develop new reusable packaging for shipping e-bikes manufacturer Riese & Müller’s products.

The latest effort comes as Riese & Müller intends to transition to reusable packaging for shipping its e-bikes and small components.

Both circular and rhinopaq are working in close coordination to develop this packaging locally in Germany.

The e-bike packaging is expected to be rolled out to selected dealers across the country by September this year.

As part of its initial plans, the e-bike manufacturer intends to adopt this sustainable change in shipping for up to 60% of its e-bike packaging and up to 70% of its small components packaging by early 2024.

Once implemented, this transition will help Riese & Müller and its dealers to minimise their overall waste generation in the retail sector by approximately 905 tonnes (t) of cardboard annually.

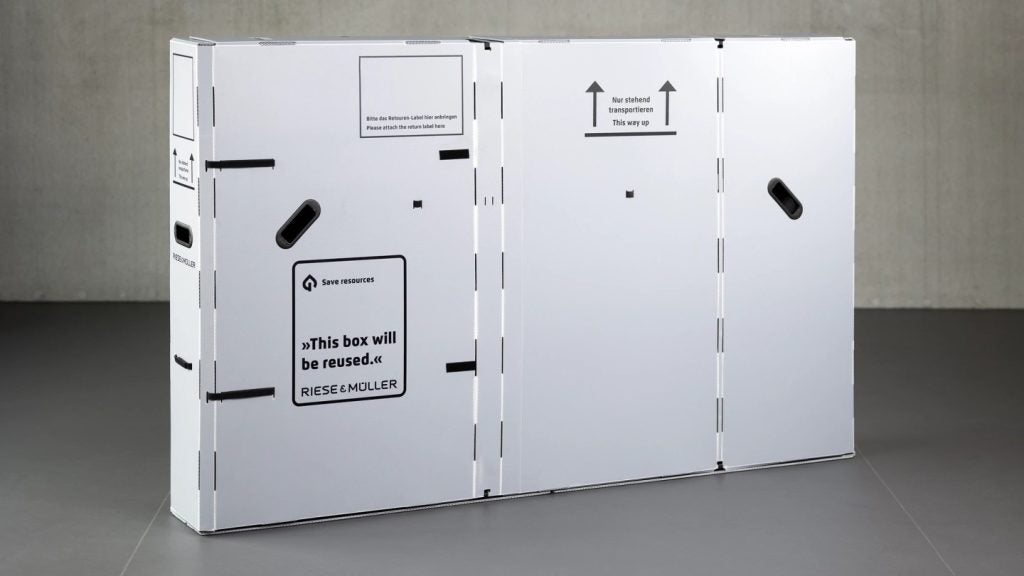

The new 'BikeBox' is entirely made using polypropylene (PP), which is regarded as a highly durable and easy-to-recycle material.

This PP material can be reused up to 30 times, saving approximately 80% of carbon dioxide compared to traditional packaging in the process.

The new boxes will be sized the same as Riese & Müller's existing cardboard boxes.

According to circular, after the e-bike products are taken out of their packaging, the BikeBoxes can easily and quickly be folded and sent back to the company via the usual transport routes.

This will further result in saving 880t of cardboard annually, circular noted.

In the case of the smaller components, circular said that its packaging is foldable and associated dealers can easily return it in bundles.

These reusable boxes can be fastened with the help of a hook-and-loop design to eliminate the requirement for adhesive tape.