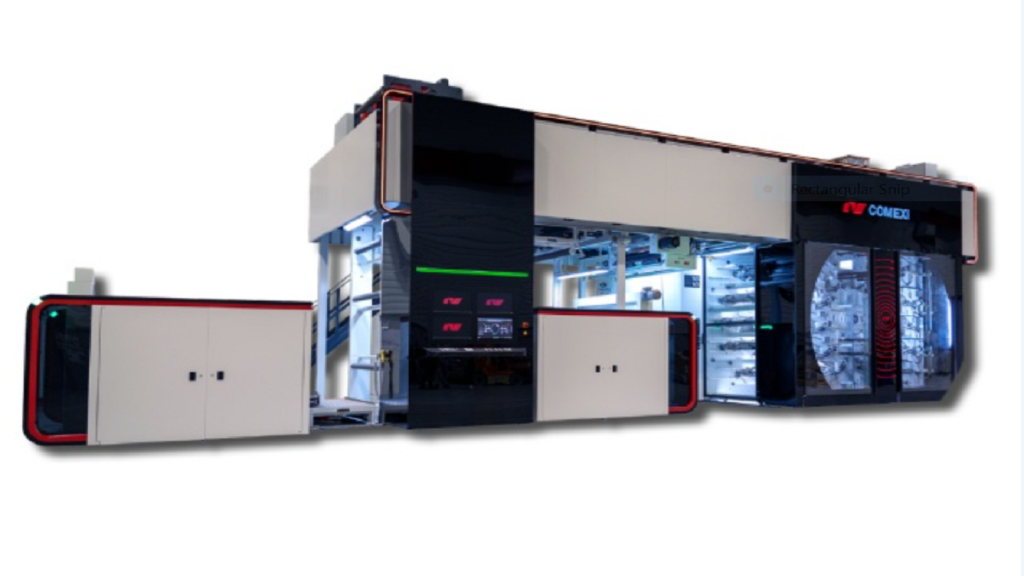

Coveris, a global packaging solution provider, has announced a €3m ($3.25m) investment in a new Comexi press to further its commitment to ‘No Waste’ through print and operational efficiencies.

The flexo print technology is set to deliver exceptional print quality and high-speed efficiencies while minimising energy consumption for each job.

Coveris will install the press at its Louth facility in England, UK, next month, with operations expected to commence by August this year.

The new 1.7m-wide web press is capable of printing with ten colours at speeds of up to 600m per minute.

It incorporates GeniusTech automated intelligence to optimise changeovers, impressions, and registration.

This investment will support the Louth facility's fresh food and beverage films, delivering capacity improvement for rapid downstream printing.

The new press will bolster the site's growth in recyclable MonoFlex and recycled ReGen extruded films.

The high-speed, fast-turnaround capabilities of the press, with reduced setup and waste, align with the company’s strategic growth plans in the produce films sector.

Coveris Louth plant managing director Paul Barber said: “We’re very excited to announce this investment and the opportunity to showcase it at the world’s leading print event alongside Comexi.

“Having made one of the packaging industry’s most groundbreaking and significant investments into ReCover at our Louth facility last year, we continue to invest in game-changing technologies for our customers.

“Offering unrivalled quality and speed alongside minimised waste, energy and process, this really does represent the future of print and we look forward to sharing the technology both with our customers and at Drupa.”

The new flexo print technology from Coveris will be exhibited at this year's Drupa event in Düsseldorf, Germany, which runs from 28 May to 7 June.

Last week, Coveris announced an investment to increase the production capacity for medical device packaging at its sites in Rohrdorf and Halle, Germany.