DS Smith has announced a partnership with Nafici Environmental Research (NER) to undertake a trial application of waste cellulose materials in paper production via the addition of pulp drawn from waste agricultural products, as well as from virgin and recovered fibres.

This initiative is part of Smith's 'Now and Next' sustainability strategy.

As per the company’s research, leveraging these materials could reduce reliance on virgin fibres in the papermaking process by up to 10%.

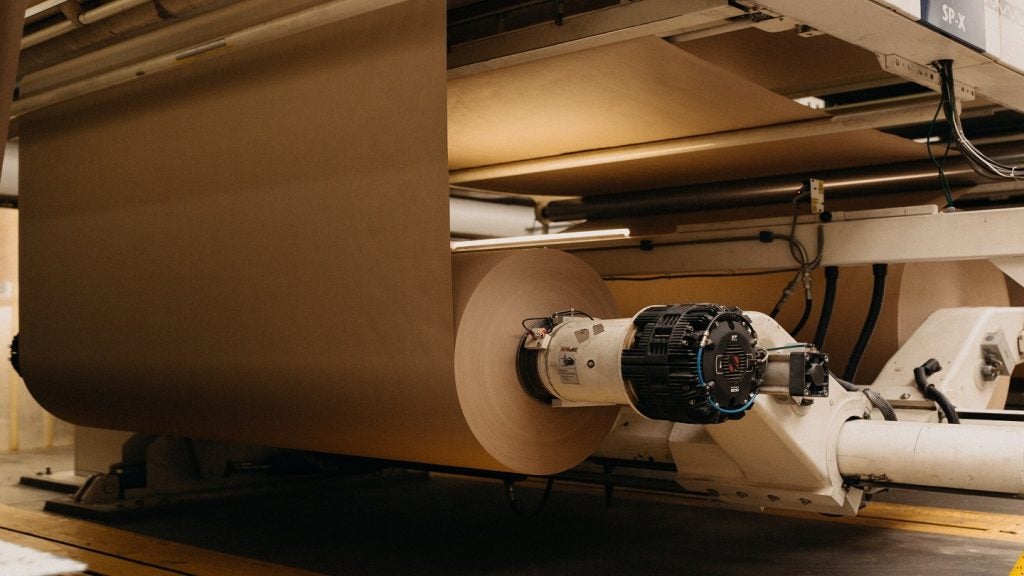

The trial, which will take place at Smith's Kemsley Mill research and development (R&D) facility in Kent, England, UK, will utilise NER's EcoPulping process.

This process is designed to consume less water and energy than traditional pulping techniques while potentially enhancing the strength of the cardboard produced.

Smith materials development director Nick Thompson said:: “DS Smith has built a reputation for being at the forefront of innovation in the recycling aspect of its operation, in part demonstrated by the investment into the R&D Fibre & Paper Development Lab (based at Kemsley Mill) and our ongoing partnership with Nafici.

“Businesses are keen to understand how they can adopt more circularity into their supply chains and finding secondary uses for what are currently seen as waste materials are key to that."

This collaboration with NER, an R&D specialist in converting cereal straws into unbleached paper pulp, is the latest development in Smith's commitment to sustainability.

In 2023, Smith teamed up with Eat Happy to develop fully recyclable sushi packaging, which is expected to prevent up to 1,250 tonnes of plastic waste annually.

In November last year, it also announced investing €90m ($98.25m) to support the sustainable transformation of energy supply at its Rouen paper mill in Normandy, France.