H.B. Fuller, one of the world's leading adhesive companies, has announced that its Lüneburg and Nienburg manufacturing sites in Germany have been awarded the International Sustainability and Carbon Certification (ISCC) PLUS.

The company claimed that this certification indicates its commitment to sustainability and compliance with international standards throughout its supply chain.

The ISCC PLUS certification is a globally recognised system that validates the sustainability of various feedstocks, including biomass, circular materials, and renewables.

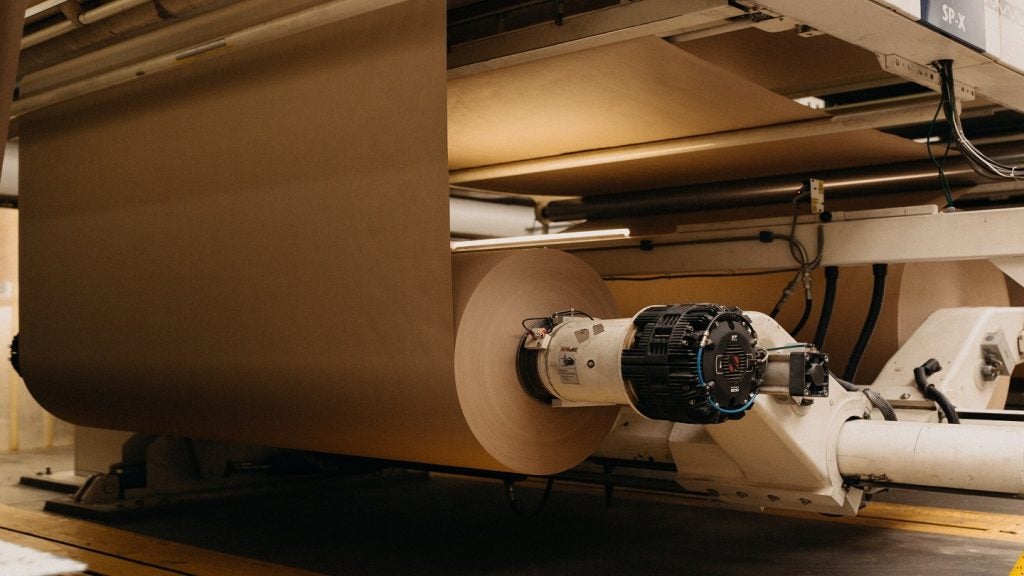

The Lüneburg plant is now certified as a compounding site for the mass balance approach. It produces Advantra Earthic 9370 using this method.

The mass balance approach is a calculation-based method that is utilised to track the inputs and outputs of mass within a system or process.

Advantra Earthic 9370 is a near-carbon-neutral adhesive that incorporates a significant proportion of sustainable and biocircular raw materials and is ideal for use in various packaging industries, including e-commerce, food, personal, and home care.

Meanwhile, Fuller's Nienburg site has been certified as a speciality chemical plant. It manufactures adhesives such as Rakoll 5010, 5016, and 4020.

These products partly replace fossil raw materials with bioattributed materials also through the mass balance approach, thereby reducing carbon dioxide emissions and offering potential for broader application in industries such as textiles and automotive.

Fuller's global quality and sustainability director Nathalie Ruelle said: “By continuously exploring ways to reduce our carbon footprint and implementing new approaches, such as mass balance, we can now offer more solutions with verified, tracked, biobased and recycled raw materials throughout the entire supply chain.

“H.B. Fuller is on the right path to facilitate incremental transition to alternative materials and reduce emissions, while helping our customers achieve their own sustainability goals.”

In November last year, Fuller partnered with Graphic Packaging to demonstrate the necessity of collaboration across the industry's value chain.