Shrink film manufacturer Shantou Mingca Packaging and ExxonMobil Asia Pacific Research & Development have introduced a double bubble polyethylene (PE)-based shrink film (PEF) solution.

This next-generation polyolefin shrink film (POF) has been developed using ultra-low density Exceed XP performance PE.

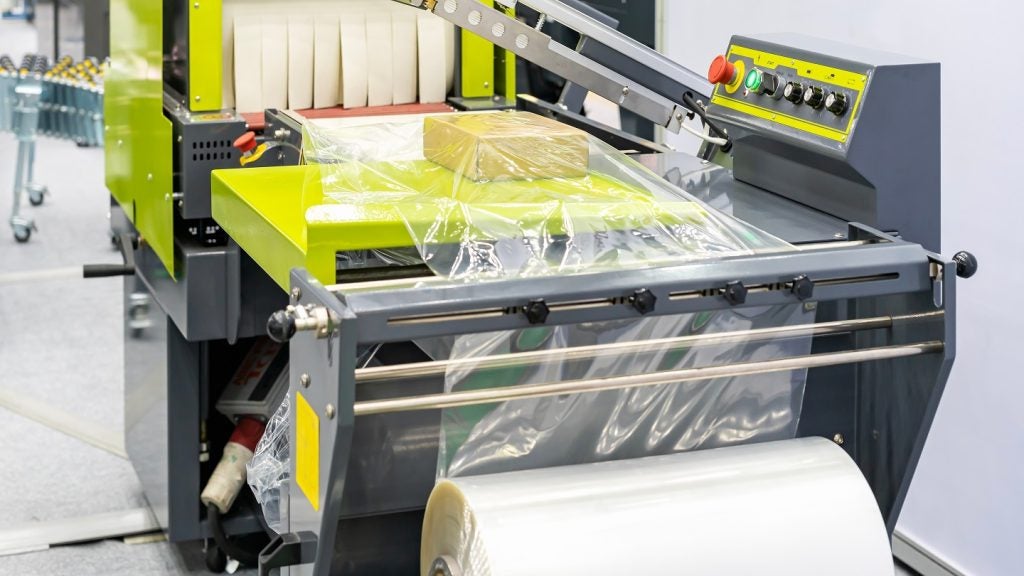

The new shrink film solution is reportedly versatile and suitable for a wide range of products, including personal care products, electronics, medicines, household items, and others.

Its PE-based structure is designed to facilitate easier mechanical recycling than traditional POF solutions.

The film’s recyclability has been third-party certified by TÜV Rheinland.

The new PEF solution has the ability to shrink more than 70% upon heating and its snug-fit feature enhances the product's shelf appeal.

With optical properties featuring haze as low as 2.8% and gloss up to 86GU, the Exceed XP-based PEF stands out for its high levels of clarity and shine.

According to the partners, converters can easily transition to this new PEF shrink film using double bubble technology, with minimal adjustments required for existing POF production lines.

Mingca general manager Liu Kun said: "From raw material suppliers, film converters, to brand owners, the value chain has ambitious recyclability goals.

"PEF is a game changer when it comes to the recyclability of shrink films, bringing more capabilities to the packaging world to help contribute to a circular plastic economy."

In September last year, Pactiv Evergreen partnered with ExxonMobil to leverage its advanced recycling technology, Exxtend, to develop and provide certified-circular polypropylene packaging products.