A collaboration involving PepsiCo and its flexible food packaging supply chain partners has launched new premium snack packaging containing 50% recycled plastic.

The new packaging fulfils stringent food-contact requirements and was launched for PepsiCo's Sunbites brand in the UK and Ireland late last year.

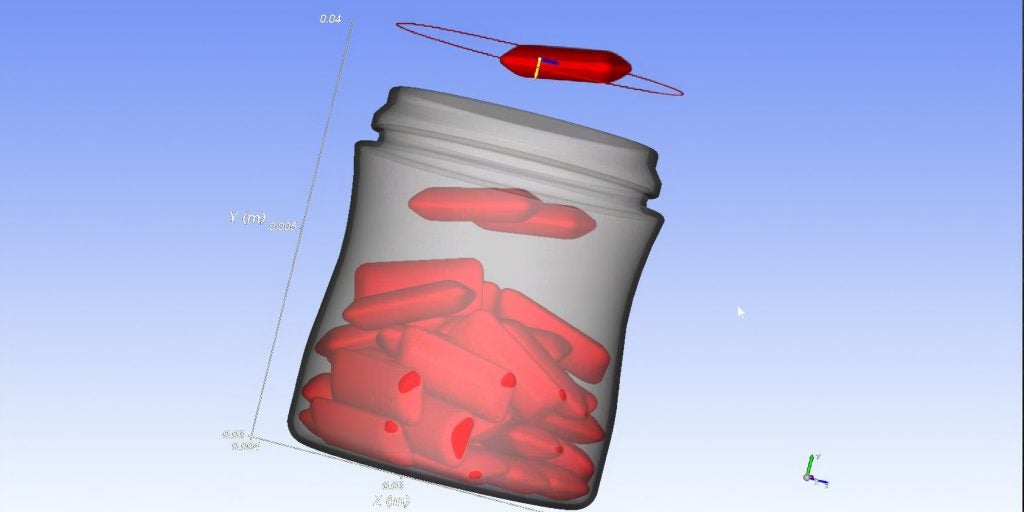

The creation of this packaging material utilises an advanced recycling process that transforms plastic waste into food-grade packaging material.

This process complements mechanical recycling and complies with EU regulations regarding sensitive and medical device packaging.

As part of the project, GreenDot, a company focusing on developing solutions and assets to address the plastic waste crisis, played a key role in sourcing and supplying post-consumer plastic packaging waste.

This waste was then converted into TACOIL (a form of pyrolysis oil) using Plastic Energy's technology.

With this pyrolysis oil, INEOS Olefins & Polymers Europe produced recycled propylene (PP), an alternative to traditional fossil feedstock.

The PP was then processed into virgin-quality recycled PP resin at the company's Lavera plant in France.

The initiative is part of PepsiCo Positive (pep+), PepsiCo's comprehensive transformation strategy that aims to phase out virgin fossil-based plastics in its crisp and chip bags across Europe by 2030.

The recycled polymer content in the packaging is certified under the International Sustainability and Carbon Certification PLUS scheme, ensuring its traceability.

PepsiCo Europe CSO Archana Jagannathan said: “At PepsiCo, we are proud to work with our industry partners towards more sustainable packaging solutions.

“We are excited about the Sunbites new packaging in the UK, and we look forward to learning from this pilot market and expanding it across more countries in the near future. Collaboration is key to progressing on our ambition to eliminate virgin fossil-based plastic in all our crisp and chip packaging in Europe by the end of 2030.”