Research has found that there have been approximately 139m metric tons of single-use plastic waste in the year 2021. This disposable plastic is utilised in day-to-day life and it is estimated that around 50.1% is utilised just once and then thrown away.

Scientists are putting tremendous effort into finding a sustainable solution. The first known bioplastic PHB, polyhydroxy butyrate, was first discovered in 1926 by Maurice Lemoigne. There has since been a rising interest in the use of biodegradable films. Consciousness about the environment has also accelerated the usage of films.

Recent innovations in film manufacturing include Dow and Klöckner Pentaplast's recyclable vacuum film and Berry Global's form-fill-seal film for powdered products.

Biodegradable films consist of additives with plastic as a component. The benefit of adding these enzymes is that they enable the plastic to break down. The plastic can be decomposed by the addition of living organisms, for example, fungi or bacteria, with or without impact on the environment.

The benefits of biodegradable films are that they decompose naturally and the end result for the environment is a little less harmful.

Reduced carbon emissions

One of the prominent benefits of utilising these films is the remarkable reduction in carbon emissions. The process of plastic generation generates carbon as it has been estimated that in the year 2019, approximately 1.81bn tons of greenhouse gas emissions were generated by plastic. Out of which, 90.1% of emissions come from their production. In fact, the conversion of plastic into fossil fuels also generates enormous carbon.

Substituting packaging with biodegradable films helps in reducing carbon emissions. According to research, 90.1% of current plastics can be easily derived or manufactured from plants.

Eco-friendly solution

Since these films are made out of natural materials for example, cellulose, starch, and proteins. They break down conveniently into natural substances such as carbon dioxide, biomass, and water.

It has been estimated that it takes 6 months to 1 year in an environment with proper exposure to oxygen.

Low energy consumption

The initial investment for developing these films might be a little expensive but in the long duration, these films require a lesser amount of energy.

Recyclable material

It has been researched in an analysis that approximately 36.1% of all the plastics produced are utilised for the purpose of packaging and about 85.2% of them end up as unregulated waste. While biodegradable films are recyclable cost-efficiently.

Reduced petroleum consumption

Oil is an imperative ingredient in the manufacturing of conventional plastics. Approximately 8.5% to 10% of the total oil supply goes to making plastic.

When biodegradable material is incorporated while making packaging films it consumes significantly less petroleum.

Some of prominent types of biodegradable films are:

- Starch-based biodegradable films

These films are made up of potatoes, wheat, or corn. These starch-based plastics are complex mixtures of starch consisting of compostable plastics for example PBAT, PLA, PCL, PBS, and PHA.

Usually, this form of biodegradable film meets American Standard for Testing Materials for the purpose of composability as it is able to degrade approximately 91% within 180 days under specific situations.

| Pros | Cons |

| There is no net rise in CO2 emission in the global system | Less mechanical strength |

| Residual material is compostable and biodegradable | Limited shelf life |

| There is prompt degradation of the litter | |

| Lesser content of fossil fuel |

These types of films are useful in packaging carrier bags, refusal sacks, food films, agricultural films, and mailing films.

- Additive based biodegradable films

Additives can be mixed with conventional polymers to fabricate oxo-degradable to facilitate microbial attack.

Oxodegaradable films are manufactured by mixing an additive within the regular polymers to provide an oxidative. This typically takes 6-8 months in the environment with adequate exposure to oxygen.

| Pros | Cons |

| Cheaper than starch-based plastics | Degradation depends on access to air |

| Can be made with standard machinery | These are not designed to degrade in landfill |

| Certified to be non-toxic | The exact degradation rate can be deduced |

Some of the applications are garbage bags, trash bags, compost bags, mulch bags, and carrier bags. Furthermore, bioplastics can be divided into non bio degradable and biodegradable plastics. The global production capacities of these bioplastics in accordance with the market segment are as follows:

Packaging (Rigid and Flexible): Polypropylene (PP), Polypropylene(PP), cellulose bio polyethylene (PE), Bio polyethylene terephthalate (PET), Polylactic acid (PLA), polybutylene succinate (PBS), and Polybutylene adipate terephthalate (PBAT) 1071 thousand tons. This is the largest industry capacity.

Building and construction: Polyethylene terephthalate (PET) and Polypropylene (PP) etc holds 20.8 thousand tones.

Coatings and adhesives: Polyhydroxyalkanoates (PHAs), Starch blends, and Polybutylene adipate terephthalate hold 35 thousand tones

Electronics: Cellusolse films, polypropylene(PP), polybutylene succinate (PBS) 57.5 thousand tones hold 57.8 thousand tons

Agriculture & horticulture: Polypropylene (PP), starch blends, polybutylene succinate hold 97.3 thousand tones holds 97.5 thousand tons

Automotive & transport: Poly trimethylene terephthalate (PTT), cellulose films, and Polybutylene(PP) and PBS polybutylene succinate hold 159 hundred tons

Consumer goods: PTT poly trimethylene terephthalate, Cellulose goods, Polypropylene, Polyhydroxyalkanoates (PHA), Polylactic acid (PLA), Polybutylene adipate terephthalate (PBAT) hold 312 thousand tons

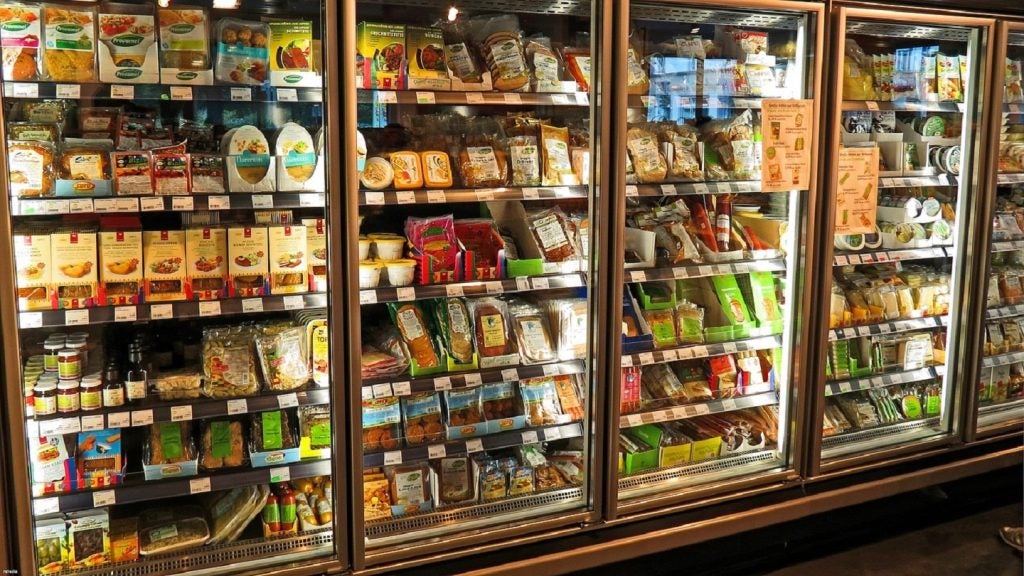

Biodegradable food packaging films market

According to research, the biodegradable food packaging films market shows the global market is set to exceed $1.4bn by the year 2029. The growth drivers of the market are rising concern for the environment and food safety.

The market in the Asia Pacific region is anticipated to render lucrative opportunities for the market. Other than this, the market in Europe is also projected to occupy a remarkable share of the biodegradable food packaging film market.

In 2022, the capacity of Asia in producing bioplastics was 41.4 billion tons, Europe holds 26.5bn tons, North America holds 18bn tons, Latin America holds 12.61bn tons, and Australia holds 0.5bn tons of capacity.

About the author: Sham Ambhore is part of the media team at Research Nester.