Global healthcare packaging company TekniPlex Healthcare has announced its plans to open a new 200,000ft² production facility in Madison, Wisconsin, US.

This is set to be the company’s second manufacturing plant in the city.

The facility will boost TekniPlex Healthcare’s global capacity and will further mark the expansion of its footprint in the North American region.

It is expected to become operational early next year.

Once open, it will operate in compliance with the International Organization for Standardisation's 13485:2016 quality management system.

This system certifies that TekniPlex is eligible to provide medical devices and associated services to fulfil its associated regulatory and customer requirements.

The facility will have new production equipment that will help in increasing TekniPlex’s existing lamination capacity for a wide variety of materials while ensuring shorter lead times and higher packaging quality.

These packaging materials mainly include paper, foil, polyethylene terephthalate, nylon, ethylene and acrylic acid, and ionomer in peelable/non-peelable structures.

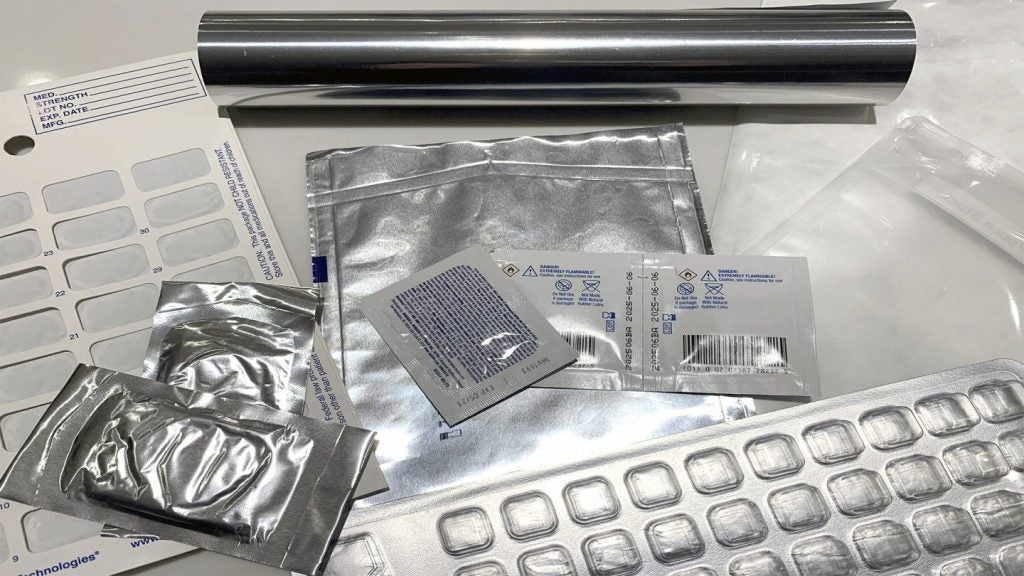

TekniPlex said that currently laminate and coated products are utilised for several applications, including in contact lens packaging, plastic pouches, flexible foil, procedural tools, and blister lidding, as well as in the pharmaceutical, medical device and diagnostics sectors.

Furthermore, the new plant will feature coating and lamination assets to enhance the company’s capabilities to produce a variety of products, including reinforced papers and coated Tyvek.

TekniPlex Healthcare CEO Chris Qualters said: “Our business has grown substantially across the medical device, pharmaceutical and diagnostics sectors, and the new Wisconsin location will help TekniPlex provide our customers access to the most advanced process technology and available capacity, solidifying our industry-leading quality and delivery.”

Additionally, the facility will be equipped to support flexographic printing, which allows quick changeover to accelerate customer delivery times and creates a zero-waste scenario in the production environment.

TekniPlex said that all the new equipment in the Wisconsin plant will use the latest technology to minimise energy consumption and process waste with the help of a factory-wide trim waste recovery system.

This in turn will further maximise the facility’s environmental efficiency.