Global colour and additive masterbatch manufacturer Tosaf has announced the launch of a new ultraviolet (UV) barrier solution for thin transparent food packaging applications.

Referred as “UV9389PE EU”, the solution has been designed to protect the food from wastage resulting from premature spoilage.

It helps in ensuring that clear packaging films, even at low thickness, provide high blocking effect against UV radiations, with wavelength ranging from 200nm to 380nm.

This UV barrier capability further helps in protecting the food products from vitamin and flavour loss as well as from discolouration, all of which are the degrading effects of artificial light.

The food products are mainly exposed to artificial light during shipping, storage, and also while they are on the supermarket and grocery stores’ shelves.

According to Tosaf, the optical properties, especially the transparency, of films finished using its newly developed barrier solution are “almost completely” retained, in comparison to similar, traditional mineral based products.

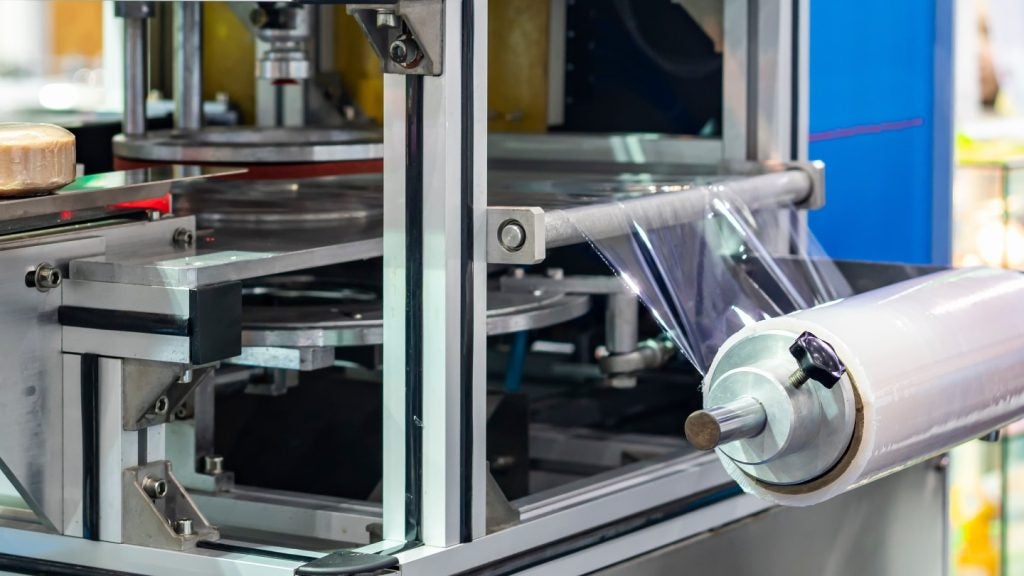

In addition, UV9389PE EU provides high efficiency even at “very low dosages” or when it has minimal influences on the behaviour of clear films during production and processing stages, including printing and lamination processes.

Apart from food packaging, Tosaf’s new UV radiation blocking solution can be used for a wide range of industries, where providing protection against UV radiation to sensitive products and goods is crucial.

Tosaf said that UV9389PE EU will also complement its existing portfolio, comprising stabiliser masterbatches for maximising resistance against UV radiations.

These stabiliser masterbatches are used for the production of stretch films, shrink, agricultural films, industrial packaging and big bags, including flexible intermediate bulk container (FIBC).

Earlier in May, Tosaf Color Service launched a new masterbatch carrier system for food contact applications.