UFlex, a multinational flexible packaging company, has reported a notable 12.3% year-on-year (YoY) increase in its unaudited consolidated net revenue for the first quarter (Q1) of financial year 2025 (FY25), amounting to Rs36.82bn ($438.56m).

This growth also reflects a 5.3% rise quarter-on-quarter (QoQ).

During the quarter, the company's packaging films sales volume saw a 13% increase compared to the same period last year and a marginal 0.9% QoQ growth.

The sales volume in aseptic packaging also showed positive trends, with a 3.2% YoY increase and a 6.8% rise from the last quarter.

UFlex's total production volume reached 167,853 tonnes (t), marking a 15.6% growth YoY.

Its operational earnings before interest, taxes, depreciation, and amortisation (EBITDA) for the quarter stood at Rs4.65bn, a significant 45% increase YoY and a 2.2% increase QoQ.

The operational EBITDA margin was reported at 12.6% for the quarter, compared to 13% in the previous quarter and 9.8% in the same quarter of the previous year.

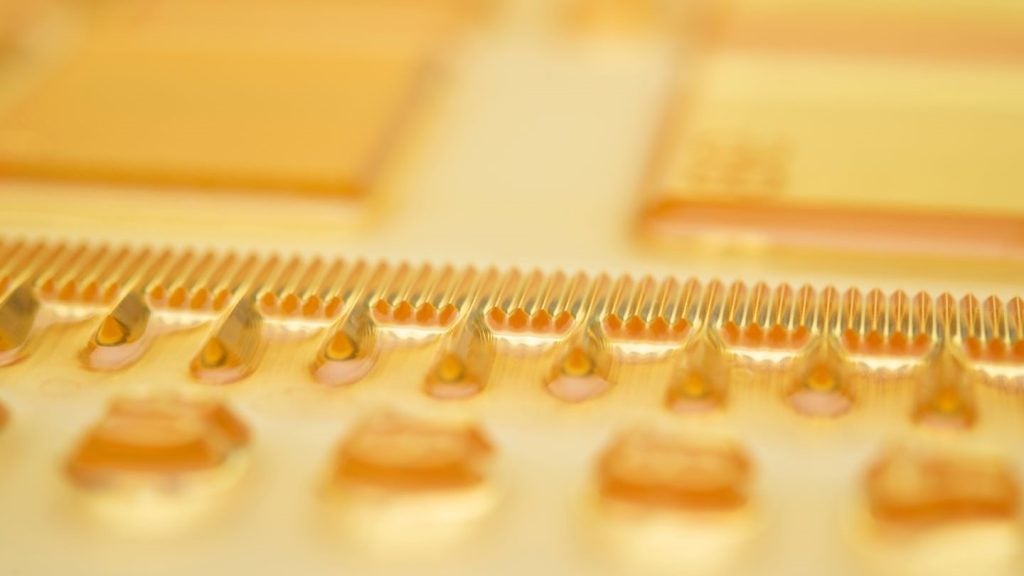

In a strategic move to expand its global footprint, UFlex announced the commissioning of a new 6.5m-wide cast polypropylene (CPP) film line in Russia through its subsidiary Flex Films Rus.

This line, with an installed capacity of 18,000t per annum, will complement the existing capacities of a 30,000t per annum biaxially oriented polyethylene terephthalate (PET) film line and an 8,000t per annum plasma-enhanced metalliser.

UFlex Group CFO Rajesh Bhatia said: "We had a good first quarter, and are on track for a strong recovery in the global packaging films business both in volumes and margins.

“The aseptic packaging business recorded the highest-ever quarterly production and sales volumes and with the debottlenecking getting completed later in the year, we will witness strong volume growth from Q4 FY25 onwards.

"The backward integration strategy with the commissioning of the first PET chips plant in Panipat, India, has been a huge success, and with the planned commissioning of the PET chips plant in Egypt later in FY25, UFlex will become even more self-sufficient in its raw material requirements."