Finnish company Valmet has received a new order to provide a recovery boiler and upgrade the existing evaporation system at DS Smith’s paper mill in Viana, Portugal.

The companies have not disclosed the value of this order.

Valmet said that the latest order is booked under the orders received in the first quarter of the current year.

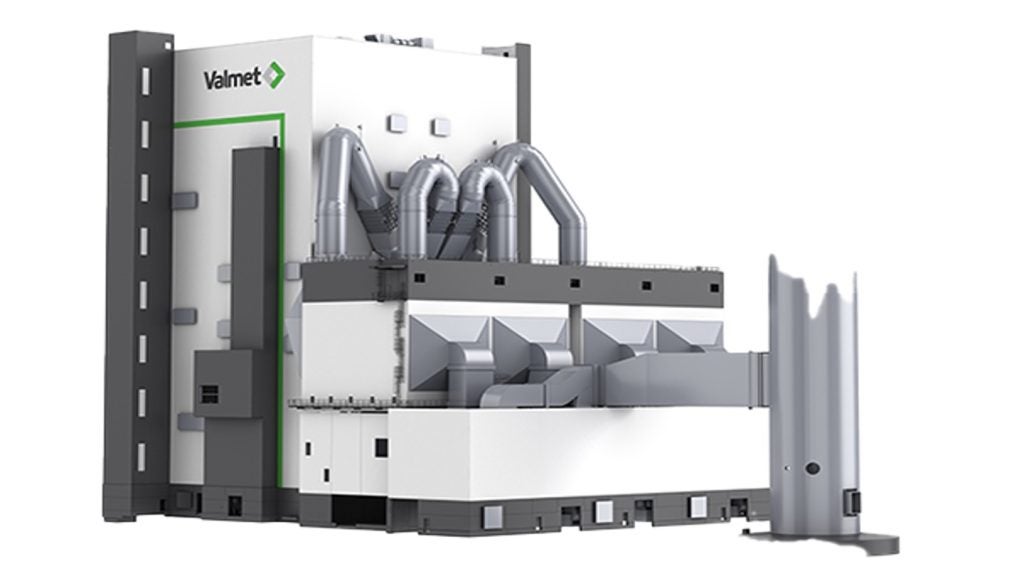

As part of this order, the Finnish company will deliver a new high-power recovery boiler along with its associated emission control solutions and non-condensable gas (NCG) handling systems.

With its high power capacity, the new boiler will provide maximum steam and energy efficiency to DS Smith’s paper mill.

The new emission control systems, including Valmet’s electrostatic precipitator, will deliver effective dust removal capabilities to the plant while ensuring low emissions.

Additionally, Valmet will deliver a DNA automation system, including advanced process controls and an operator training simulator to help in controlling the recovery boiler.

The company will provide a six-effect configuration and a set of Tubel and Tube technologies to upgrade the evaporation system, delivering mechanical reliability to the system while boosting the heating area with 10,100m².

Deliveries under the latest deal are expected to commence in the first half of 2025.

Valmet recovery, pulp and energy vice-president Jussi Mäntyniemi said: “Our delivery for the chemical recovery island of DS Smith Viana mill enables the mill to improve energy efficiency, reduce emissions and improve the availability of the whole pulp production process.

“The recovery boiler and evaporation projects are a continuation of the lime kiln upgrade project started last year.”

The latest order to Valmet has been awarded as part of DS Smith’s ongoing effort to upgrade its Viana mill with new machinery to help minimise carbon dioxide emissions.

This €145m ($158m) multi-year upgrade programme was launched by DS Smith in April.

DS Smith paper and recycling head Niels Flierman said: “As one of our larger mills, Viana has a huge role to play in our commitment to remain at the forefront of the market, and to lead the way in the race to net zero in the paper industry.”