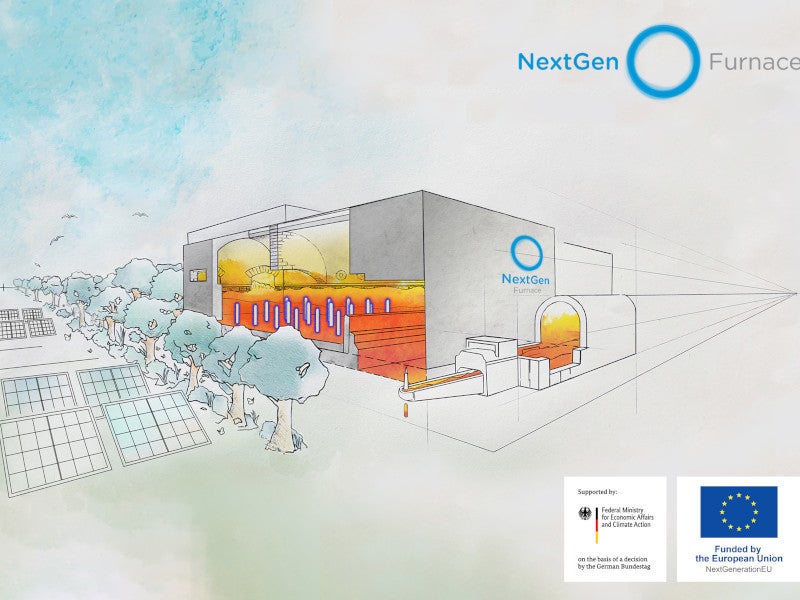

Ardagh Glass Packaging, a global leader in sustainable packaging solutions, is nearing the completion of its NextGen Furnace construction. The revolutionary project promises to make significant strides to reduce carbon emissions while advancing sustainability in the glass packaging industry.

Currently under construction at Ardagh Glass’ Obernkirchen facility, the NextGen furnace is expected to commence production of commercial glass containers by the end of 2023. The commissioning is a crucial step to achieving Ardagh’s 2030 Sustainability Strategy, while also being a key achievement in the company’s journey towards decarbonisation.

The large-scale hybrid electric furnace also makes Ardagh Glass a frontrunner in sustainable glass manufacturing by combining productivity and environmental responsibility.

Ardagh Glass NextGen furnace details

The NextGen furnace will use high levels of recycled glass cullet in its production process. The furnace will invert the traditional energy mix for container glass production of 90% gas and 10% electricity. It will be achieved by using an energy mix of 80% renewable electricity and 20% gas.

The 20% gas from the outset will be replaced by green hydrogen as part of phase two developments, further reducing CO₂ emissions.

The contemporary use of gas firing will be replaced by electrodes present in the furnace to melt raw materials and cullet into molten glass, resulting in a substantial reduction in the carbon footprint associated with glass packaging production.

The industrial technology used in the furnace contains an additional gas filtration process that uses advanced filter technology to combat other emission elements. The technology reduces emission levels to substantially below the current industrial standards, resulting in a more efficient furnace with significantly reduced gas consumption and carbon emissions.

In combination with the company’s plan to use 100% renewable electricity at their facilities by 2030, the NextGen Furnace will add to its Sustainability Roadmap.

Sustainability features of the NextGen Furnace

One of the most significant aspects of the NextGen Furnace is its potential to substantially reduce CO₂ emissions. With its reliance on predominantly renewable electricity, the furnace will be able to achieve an impressive 60% reduction in emissions within its operations, which will substantially contribute to the group’s sustainability targets and commitment to decarbonisation.

The NextGen Furnace is not just environmentally friendly but also an economic powerhouse with the capacity to produce up to 350 tonnes (t) of glass bottles per day. Production will be primarily in amber glass, but it has the flexibility to produce bottles in a range of other colours.

The company intends to adopt the NextGen Furnace technology and other low-carbon solutions across their facilities in the future.

The growing demand for stringent pollution control devices could also enable further capital upgrades to the furnaces and production facilities in the future.

Marketing commentary on Ardagh Group

Headquartered in Luxembourg, Ardagh Group has a significant global presence including the Americas, Europe, and Africa, serving as a supplier of packaging solutions to brand owners around the world.

It operates an extensive network of production facilities, encompassing 65 locations across 16 different countries, with 21,000 employees worldwide.

Ardagh Group is committed to sustainability as the supplier of infinitely recyclable metal and glass packaging with an annual sales revenue of approximately $10bn.

Agencies such as Bundesministerium fur Wirtschaft und Klimaschutz (Federal Ministry for Economics and Climate Protection) and KEI: Klimaschutz in Energieintensiven Industrien (Climate Protection in Energy-Intensive Industries) have provided grants to qualifying energy-intensive industries including the Ardagh Group for its sustainable packaging in Germany.