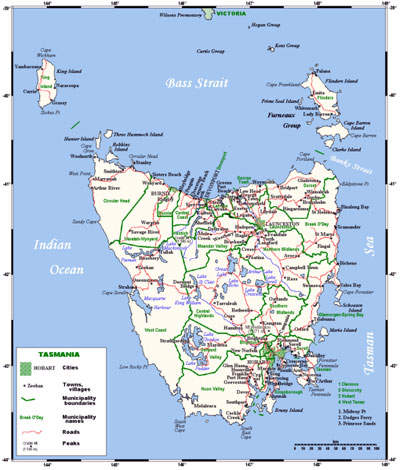

James Boag & Son of Launceston, Tasmania, is the fourth largest brewer in Australia. The company is a subsidiary of the large Philippine food and drink conglomerate San Miguel, following a friendly acquisition in 2000. Since then the Boag brands have been developed and this has resulted in increased popularity and sales.

A new expansion programme for the brewery was planned over the three years following the takeover to further develop Boag beers as international brands. The three-year investment programme cost over AU$55m.

The first phase of the expansion involved an extensive upgrade of the bottling and packaging processes at the brewery. This required an investment of AU$18m and was completed in November 2004. The brewery employed 142 people and produced over 46 million litres of beer per annum. In 2004-05 the Boag Brewery was expanded to occupy the complete block enclosed by William, Tamar and Shield Streets and The Esplanade in Launceston.

On 1 December 2009, Lion Nathan opened a new state-of-the-art brewhouse as part of the $25m expansion. The brewhouse was completed in 18 months and will add capacity for another 50-million litres of beer product, which equates to around five-and-a-half million extra cases of Boag’s Premium, Boag’s Draft and Classic Blonde (much of this would be for the Australian domestic market).

The expansion programme received financial backing from the Australian Government under the Enhanced Project By-Law Scheme up to $17m.

Contractors and construction

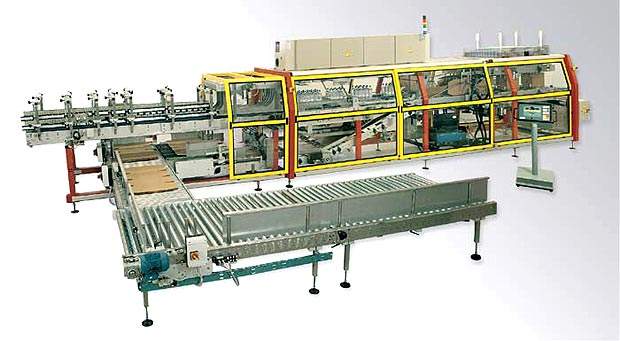

JL Lennard Engineering was awarded the contract to supply and install a Krones high-speed bottling line at the Launceston brewery and was responsible for engineering, procurement and construction (EPC) and project management (JL Lennard is the official distributor of Krones equipment in Australia).

This is the first Krones turnkey beer packaging line in Australia, and it is capable of filling 800 375ml bottles per minute to double the brewery’s previous bottling capacity. The line will initially be dedicated to package James Boag’s Premium, which is Australia’s second largest selling premium beer brand.

JL Lennard Engineering was able to custom produce all the bottle and carton conveyors for the installation at its Mansfield, Brisbane engineering workshop.

The Krones turnkey line in Launceston consists of a Pressant universal depalletiser, a Mecafill VKPV 87-valve rinser/filler/crowner bloc, a Krones/Sander Hansen pasteuriser, a Topmatic labelling machine with an automatic bulk glue system, a Variopac high-speed shrink wrapper, and three 2A linear robotic palletisers with automatic pallet infeed plus Syskron LDS line data software control.

The actual installation of the bottling line and the commissioning process was managed by JL Lennard’s project engineers. The electrical and mechanical installation was carried out by a team of Krones contract engineers. Commissioning, operation training and maintenance courses were carried out by Krones commissioning engineers from Germany.

San Miguel is keen to support their Australian subsidiary, so in addition to the plant expansion which will incorporate improvements in process and packaging, they will also construct two new glass plants in Australia at a cost of AU$140m.

In November 2007 San Miguel sold James Boag & Son to Lion Nathan Ltd for $325m. In May 2008 Lion Nathan announced that the brewery was making a modest profit and that the Boags brewery was to double its capacity with a new $25m brewhouse upgrade. Lion Nathan, the official new owner of Boags as of January 2008, announced that the multi-million dollar expansion of the brewhouse will be built at the existing site in Launceston, and is expected to double its capacity.

To be built by San Miguel Packaging Products (SMPP), the planned 250t glass plants will be constructed in Brisbane and Sydney. They will service the glass requirements of James Boag & Son and Lion Nathan Ltd (Lion Nathan is owned 40% by Kirin of Japan, which also owns 15% of San Miguel).

Packaging systems

The Mecafill VKPV filling system is an electro-pneumatic system that allows fast independent adjustable filling steps. The programme steps can be programmed and saved in a central control unit and can be recalled and set into operation at any time. This innovation allows fast change-over times for different bottle sizes and products.

The wrap-around case packer installed at the end of the bottling line is an Italian machine from SMI Pacifica, the third SMI machine at the brewery. The SMI machine, the WP-800, is the fastest model currently available and is capable of filling 80 cartons per minute. The machine runs so fast that it has to be fitted with a high-capacity OEMasterfill glue module that continually delivers small doses to the glue applicator. The WP-800 case packer also features an extended carton magazine that increases storage volume, making it easier for the line operator to maintain board supply using preformed cartons.

Krones are supplying their Checkmat fill height, missing-crown and missing-label detectors while the labellers are to feature Videojet inkjet coders, from Tronics.

Benefits

Sales of Boag beers have doubled since 1998 and annual production at the Launceston brewery has risen from 18 million litres to 31 million litres in the past three years. 60% of the brewery production is currently exported to mainland Australia and this is expected to increase to between 75% to 80% within three years following the expansion investments. Boag beers have also made an impression in world markets and will be promoted there as well.

New owners of James Boag & Son

In November 2007 San Miguel sold James Boag & Son to Lion Nathan Ltd for $325m. In May 2008 Lion Nathan made an announcement that the brewery was making a modest profit and that the Boags brewery was to double its capacity with a new $25m brewhouse upgrade. Lion Nathan, the official new owner of Boags since January 2008, said the multi-million dollar expansion of the brewhouse is to be built at the existing site in Launceston, and is expected to double its capacity.

The project will take about 18 months and will give capacity for another 50-million litres of beer product which equates to around five-and-a-half million extra cases of Boag’s Premium, Boag’s Draft and Classic Blonde (much of this would be for the Australian domestic market. Approval for the new building still has to be obtained from Launceston City Council although approval is already in place from the Heritage Council.