Egyptian Indian Polyester (EIPET) is constructing a polyethylene terephthalate (PET) resin plant in the port town of Ain Sokhna, Egypt. The new production facility will manufacture PET resin to be used to make packaging bottles for food and fast moving consumer goods (FMCG).

Construction of the $160m facility commenced in June 2011 and is expected to be completed by the end of 2012.

EIPET is a joint venture of India’s Dhunseri Petrochem and Tea (DPTL) and two Egyptian state-owned companies, Egyptian Petrochemicals Holding (Echem) and Engineering for the Petroleum and Process Industries (Enppi).

The joint venture was set up in February 2008.

DTPL owns 70% interest in the new plant while Echem and Enppi hold 23% and 7% respectively. DTPL is the second largest manufacturer of PET resin in India and the new plant is its first international venture.

It operates a 200,000tpa capacity plant in Haldia, India.

The plant will produce 420,000mt of PET plastic chips a year. About 20% of the produce will be used locally and the remaining will be exported to European and North American markets. The plant is expected to generate $700m in revenues when fully operational.

The PET resin plant will contribute towards the local community by creating 800 jobs during construction and another 500 permanent jobs when fully operational. In addition, it will create foreign exchange reserves for Egypt.

Location

The new facility is being constructed in sector 2 of the Eldorado Integrated Development and Free Zone located northwest of the Suez Gulf.

The facility was initially planned to be developed at Port Said but the implications involved in obtaining approval from the Ministry of Defence has prompted the company management to change the location.

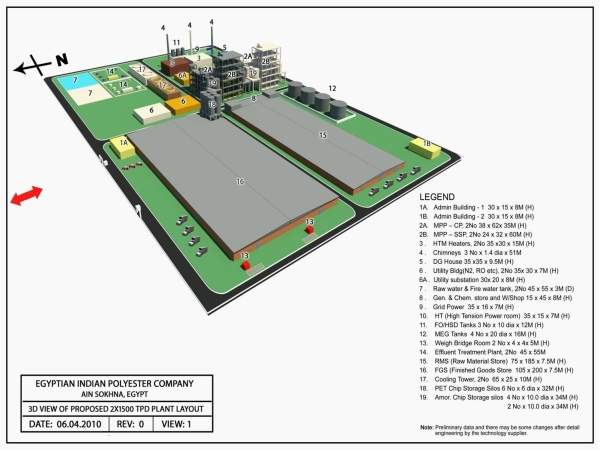

The plant will come up on a 470x300m plot in the free zone.

The site is connected to the Red Sea coastal highway. Raw materials and products will be transported along the highway directly from the Ain Sokhna port located south of the Industrial park.

The site comes under category B of the International Finance Corporation’s (IFC) Environmental and Social Review Procedures. This means the facility may result in certain social and environmental issues which can be mitigated by following the given procedures and guidelines.

The plant will conform to generally recognised performance standards and Egyptian regulatory requirements.

Facility details

The plant will include PET production units, two HTM heaters, four monoethylene glycol (MEG) tanks (20m diameter and 16m height, three chimneys and six PET chip storage silos (6m diameter and 32m height).

In addition to the main production building, the plant will have two administrative buildings, two utility buildings, a utility substation, two raw water and fire water tanks, high tension power room, two weigh bridge rooms, two effluent treatment plants, two cooling towers and raw material and finished goods storage rooms.

The plant will consume 360,000t/y of purified terephthalic acid, 142,000t/y of MEG, 1100t/d of water, 67,200MWh/y of power from local gas-fired power plant and 6000NM3/hr of natural gas from the national gas network for process heating.

During the process of PET resin production, the plant will generate 124t/d of waste water which will be treated and recycled for further use.

The other solid and hazardous waste resulting from the plant will be transported to the disposal centre in Alexandria for recycling and disposal.

Contractors

Oerlikon Barmag of Germany was awarded the engineering, procurement and construction (EPC) contract for the plant in August 2010.

Finance

IFC has committed $35m towards construction of the plant. This loan was approved in May 2011.

In addition, the Commercial International Bank and Ahli United Bank have provided $65.5m of capital and $11.3m of working capital to EIPET.