Singapore-based company Etika International Holdings (Etika) opened a new ultra-high temperature (UHT) aseptic polyethylene terephthalate (PET) bottling plant in Hawkes Bay, New Zealand.

Inaugurated in September 2011, the state-of-the-art plant is the first of its kind in Australasia and the South East Asian region. About 30 jobs have been created with the opening of the plant.

The plant is built over a 1.65ha site in the Whakatu Industrial Park in Hastings. The site is ideal for bottling operations with easy access to water and waste discharge rights.

The facility will manufacture liquid milk and juice products. Initial capacity of the plant will be 6,000 bottles an hour which is expected to increase to 30,000 in 2012.

The plant will meet growing demands for bottled and packaged products, especially infant formula, in New Zealand. The growth in demand is due to the milk contamination scandal in China in 2008.

Consumers have lost their trust in Chinese products following the scandal which led to deaths of several children.

The products manufactured at the plant will be sold in the New Zealand market as well as exported to China, Japan, South East Asia and Australia.

Financing the aseptic PET bottling plant

Etika built the new plant by establishing a joint venture (JV) with local Hawkes Bay investors through its New Zealand subsidiary Etika Dairies New Zealand (EDNZ). EDNZ holds a 60.7% interest in the JV while the remaining amount is held by Hawkes Bay investors.

Products manufactured by Etika International

The new plant will process 18 million litres of milk and juice annually. These products include vitamin-fortified flavoured milk, lactose-free milk, soy milk, milk-based energy drinks / liquid meals, standard UHT milk and liquid infant formula. Fonterra will supply the milk required for the production.

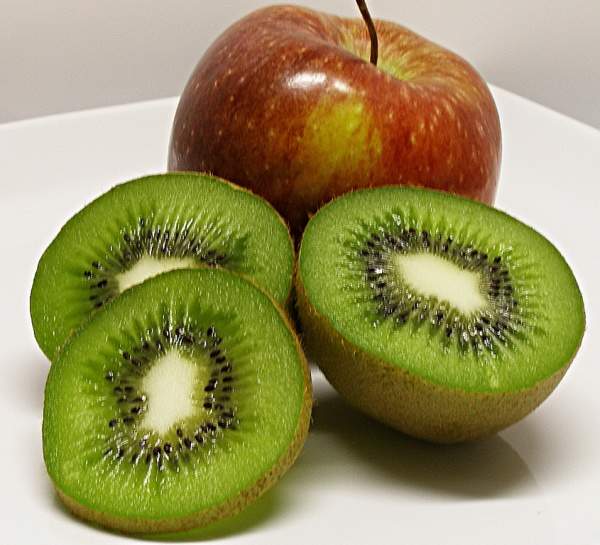

Apples and kiwi fruits procured from nearby orchards will be processed by an in-house crusher to produce 100% fruit juices.

Technology incorporated into the Singapore facility

The plant uses UHT technology to treat milk and juice before being packaged. The technology involves sterilisation of milk and juice by heating it at a high temperature of more than 135° C for a very short period of time (two to ten seconds).

After the UHT treatment, the milk and juice are packaged using non-contact aseptic cold filling technology into lightweight PET bottles. The technology enables the products to remain fresher for longer duration of time.

Preservatives do not need to be added to the products treated with UHT and they do not require refrigeration either. The technology also reduces energy consumption and saves resources.

Milk and juice produced at the plant will have a shelf life of up to six months without refrigeration.

Benefits of Etika International’s Aseptic PET Bottling Plant

UHT packaging traditionally includes polylaminated cardboard cartons. The new plant uses PET bottles to package milk and juice. It will be the first in the world to manufacture infant liquid formula in PET bottles featuring a teat cap. PET bottles are easy to use compared to cardboard cartons and can be resealed to avoid leakage.

Fully recyclable PET bottles are being produced to reduce the carbon footprint of the plant. The bottles also feature gas and UV light barrier properties, further increasing the shelf life of the products. They provide design flexibility too to increase the consumer appeal of the products.

Future plans for the company

Etika is a leading manufacturer of sweetened condensed and evaporated milk in the world.

Its products are exported to more than 40 countries.

The company is expanding its four business divisions including dairies, frozen food, packaging and others. Construction of the new plant is part of this expansion strategy.

Etika will also undertake contract manufacturing of dairy, juice and water products for third parties using the technology of the Hawkes Bay plant.

This will enable Etika to meet current and future demands for its dairy products under contract manufacturing agreements.