Mannerschnitte or Neapolitaner wafers are a well-known brand of biscuit/chocolate bar in Europe and the US. The main manufacturing facility is located at Perg, a small community near the city of Linz in Austria.

Here the company maintains one of the world’s largest wafer ovens, which can produce some 8,000 tons of flat wafers and biscuits a year. Before August 2007 this quantity of product was packaged (secondary packaging boxed) and inspected by hand using only 100 employees to ensure that all of the wafer packs were packed in the correctly labelled packaging (the company exports worldwide) and that they were completely air-tight so that the keeping quality and shelf-life

could be relied on at the point-of-sale.

With so many problems to be faced by the small workforce to keep up the quality standards in the face of increasing production, in August 2007 the company felt it needed to introduce automation into its packaging and inspection system.

New system

In August 2007 Manner AG introduced a vision system to monitor its chocolate wafer packaging process. The first requirement was that it be able to provide reliable inspection of all wafer packaging at production speeds of up to 400 packages a minute.

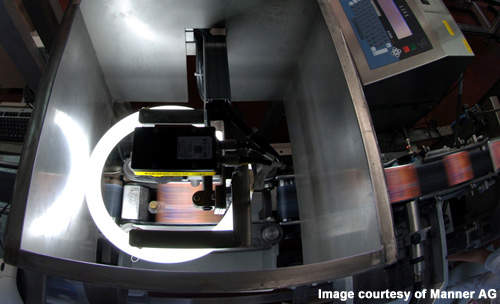

The second was that the system be flexible enough to handle a number of product variants with the operation and programming remaining simple. The system installed by Cognex was the In-Sight 5400 vision sensor in conjunction with the PatMax vision software system in a checking station just after the production line.

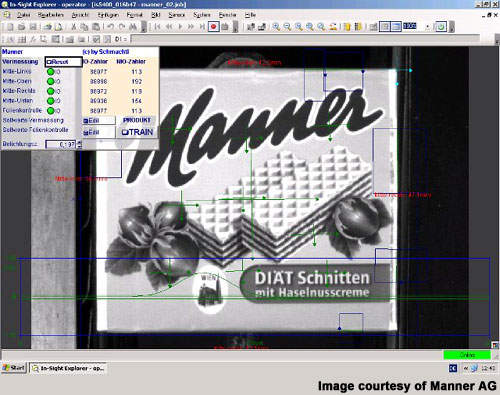

The system is able to learn and take into consideration 25 packaging colour variants and 100 texts in various languages printed on the packaging. In operation the system can distinguish between the expected text and out-of-specification text, label position, dents or tears in the packaging and the presence or absence of a particular logo, image or graphic and text on the packaging.

One of the main advantages of PatMax software is that the individual packages of Mannerschnitte wafers can flow through the inspection station on the conveyor belt without needing to be fixed in any particular position, meaning that rejection due to bad positioning is eliminated. The vision system can also detect faults with the packaging material supplied to Manner AG and this has lead to a feedback system allowing the company to maintain its standards.

Installation

The system was provided by Cognex and installed by Schmachtl from Linz, a partner system integrator (PSI) working closely with Cognex. Schmachtl carried out an extensive feasibility study in mid-2006 for the Perg plant prior to the installation to determine which system was best for the task.

The mechanical setup and installation of the system was carried out internally by Manner AG’s engineering/maintenance team and the programming of the main product lines was carried out by Schmachtl in tutorials given to the Manner engineers and operators.

Processing power

The In-Sight 5400 vision system installed is powerful and needed careful setup to take advantage of the massive processing power to achieve the high levels of production output. In the setup Schmachtl divided the entire image area of the camera for packaging inspection into 12 individually processed PatMax windows to detect out of specification packaging characteristics more rapidly, flexibly and efficiently.

The combination of twelve characteristics being inspected at the same time can give a good indication whether the product is free of defects. In an example of the way the system is used two windows are used to determine whether the packaging is centred properly and then others are used for graphics/text or shape pattern matching.

The employees on the inspection line are able to train the system (neural network) to recognise the undesirable characteristics. The rapid recognition of damaged packs means that they can be removed quickly to avoid problems further down the production line.

The introduction of the system has increased productivity by 5%. Reinhard Gassner, the plant manager, commented: "If the conveyor belt is operating at a speed of 270 packages a minute, then a few seconds of defective production means several dozen rejected packages. This is not simply a question of cost; it also has a negative effect on the production flow. Problems such as this are now in the past."

The plant now receives few complaints from customers and has gained new quality certification for its packed wafer products.