Mondi Group’s corrugated board plant in Izmit, Turkey, is also known as Tire Kutsan Izmit. The plant was one of six plants acquired by the company from Tire Kutsan, a leading corrugated packaging company in Turkey. It became part of the Mondi Group in September 2007 when a 54% stake in Tire was bought by Mondi. The plant produces various types of corrugated boxes and has a total annual capacity of 260,000t. It also specialises in die cutting, heavy duty and offset printing.

The corrugated boxes manufactured at the plant are used in the food industry for a variety of products such as biscuits, chocolates, cakes, meat, chicken and liquids, including milk and other beverages. They are also used for detergents and tissues. The facility at Izmit also has two waste-water refining plants.

Corrugated board plant production

The Izmit plant’s corrugated sheet production capabilities include various types of flutes such as B (thin), C and A (thick), E (micro), C+B and E+B (double), UPS and MPS (special).

Once the sheets are produced, they are transferred to converting lines where they obtain a wide range of printing instructions from high-tech flexo printing machines. The final step includes shaping the sheets into regular slotted and die-cut boxes.

The Izmit plant is the only plant in Turkey that has flexo printing machines with the capability to print seven colours. The plant produces flexo-printed, multi-point glued and standard corrugated boxes in seven colours.

Plant equipment installation

The Izmit plant is equipped with a corrugator, confection unit and 13 converting machines. Different types of folding, gluing and stitching machines are also installed at the facility.

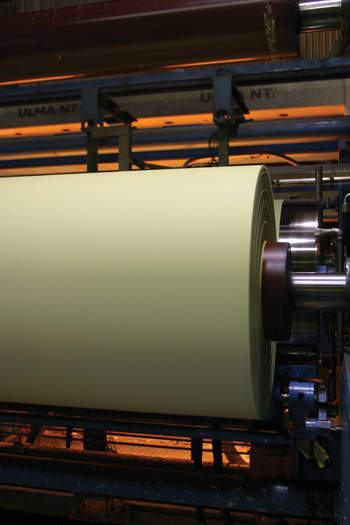

In November 2008, Mondi invested €8m in a new state-of-the-art corrugator for the plant, which was supplied by Germany-based BHS, a leading provider of customised corrugated machines for the industry.

Mondi invested in the new corrugator to produce innovative packaging solutions. The investment has also helped to increase the production capacity of the plant.

Installation of the corrugator started in August 2009. Within four weeks of start-up, the corrugator had reached its expected performance.

The plant is also equipped with testing equipment supplied by Techlab Systems (TLS), a quality solutions provider of packing, corrugated board and paper and pulp testing machines. The TLS samples crush tester and ECT pneumatic sample cutter cuts samples for use in laboratory tests for checking the quality of the board and research of corrugated cardboard.

Corrugated board plant technology

The plant employs 237 people and is ISO 9001 certificated. Its high-speed BHS corrugator is 2.8m wide and can manufacture approximately 400m of linear corrugated board a minute. It has a fully automated temperature control system and can easily be integrated into any existing corrugator line.

The pneumatic cutter creates accurate samples of corrugated board required for testing. The cutter is equipped with twin-cut blades and a sampling-positioning device, which produces a clean and parallel cut sample.

The cutter is fitted with an acrylic screen to protect the user during operation and also prevent accidents.

Benefits

The Turkish market is estimated to have the biggest growth rates in the corrugated board industry in Europe. Between 2005 and 2010, the market is expected to grow at an annual rate of 12%.

To strengthen its position in the emerging Turkish markets, Mondi acquired Tire in 2007 for €190m. Tire was part of the Ulker Group, a leading Turkish family-owned group.

Tire owns a paper mill, which annually produces 120,000t of recycled container board in Turkey. The company also owns five corrugated box plants, including the Izmit plant with a total production capacity of 450 million squared metres per year.

The acquisition has enabled Mondi to gain the leading position in the Turkish market.