MOPET Belgium is an advanced polyethylene terephthalate (PET) packaging recycling centre being developed in Neufchateau, Belgium.

The facility is being developed by Morssinkhof – Rymoplast, a recycled raw materials manufacturer, following a nine-year contract awarded by Fost Plus, a recycling solutions provider,

IDELUX, an economic development organisation in Belgium, is also supporting the project.

Morssinkhof – Rymoplast is investing in the initial phase of the recycling centre. The foundation stone for the new facility was laid in July 2024 while construction is expected to be completed in the second or third quarter of 2025.

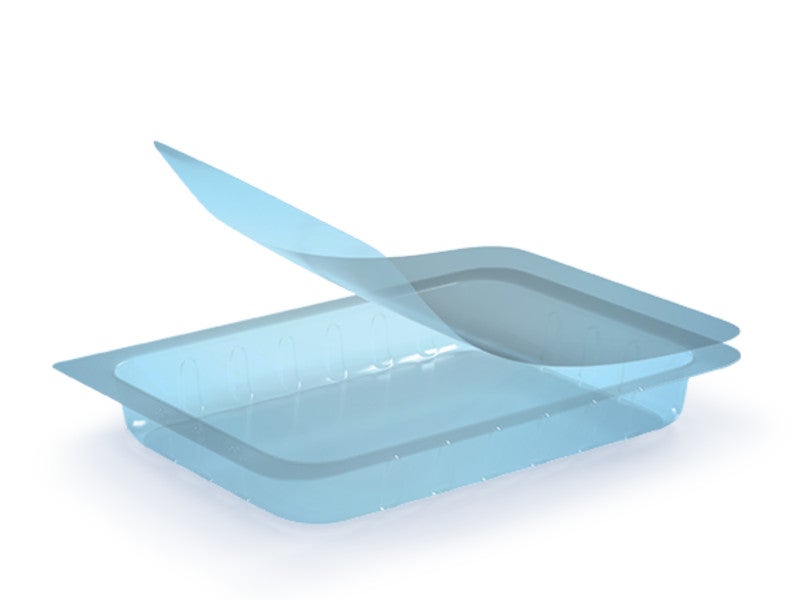

MOPET Belgium will recycle PET trays into recyclate (r-PET) on a large scale, primarily for use in the production of new trays. It will be Morssinkhof – Rymoplast’s 11th facility in Europe and its fourth recycling plant in Belgium.

The project is expected to create 90 full-time jobs in the initial phase and an additional 35 jobs in the second phase, which will involve an investment of €45m ($48.3m).

MOPET Belgium will bolster Belgium’s position as a leader in recycling and resource management. It is among six other recycling plants being developed in the country, which are expected to enable 75% of the plastic packaging materials collected in the country to be recycled domestically by 2025.

Location of MOPET Belgium’s PET manufacturing facility

The plant is being developed within the Ardenne Logistics business park of IDELUX in Neufchateau, Luxembourg province, Belgium.

MOPET Belgium PET recycling facility details

The MOPET Belgium PET recycling facility will have a recycling capacity of 40,000 tonnes per annum (tpa) of PET. It will recycle approximately 10,500tpa of trays and 17,500tpa of bottles, including opaque PET bottles.

With a focus on sustainability, the facility will purify the water used in the recycling process through state-of-the-art technology, which will be reused, thus protecting the natural beauty of the Luxembourg province.

The PET required for the facility will be collected using the New Blue Bag plastic packaging collection method launched by Fost Plus throughout Belgium in 2019.

Virtually all plastic packaging waste in addition to the usual plastic bottles and flasks can be put in the plastics, metals, and drinks packaging (PMD) bag. This ensures that plastic packaging waste such as yoghurt pots, butter tubs, and plastic bags can be selectively collected and recycled.

PET recycling process at MOPET Belgium

The PET recycling process involves several steps starting with the sorting of the bales to remove impurities.

The process includes post-sorting the items into different levels to optimise the quality of the secondary raw material from other materials such as HDPE caps, followed by grinding into flakes, cold washing, hot washing and drying on separate processing lines.

Finally, they are reconverted into raw material or granules to produce new packaging through a regranulation and post-condensation process.

The partners are planning to subject the PET, whose quality no longer meets the requirements, to a semi-chemical recycling process named CuRe Technology, which is currently being developed in the Netherlands.

The CuRe technology is primarily used to produce transparent recycled PET out of complex and coloured packaging and will ensure that all collected PET packaging will be used in high-end applications.

Marketing commentary on Morssinkhof – Rymoplast

Founded in 1960, Morssinkhof – Rymoplast is one of Europe’s largest producers of high-quality recovered raw materials and serves small companies in the plastics processing industry to the world’s largest multinationals. It has 11 locations across Europe, each specialising in specific activities.

Morssinkhof – Rymoplast’s primary focus is on recycling four main types of plastic: high-density polyethylene (HDPE), low-density polyethylene (LDPE), PET, and polypropylene (PP).

The company purchases well-sorted post-consumer plastic waste and scrap streams from collection systems and clean industrial waste from the plastics processing industry. These materials are converted into high-quality raw materials, serving a diverse international customer base, from small plastics processing companies to the largest multinationals.

As a plastics recycling partner, the company collaborates with other organisations to optimise their plastics cycles. By supplying high-quality recycled raw materials, the company enables manufacturers to develop more sustainable packaging solutions for plastic products.