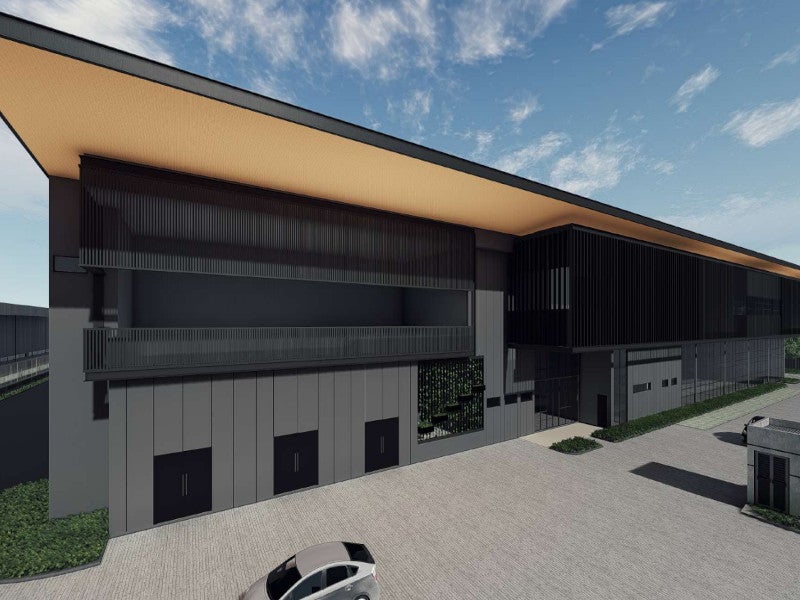

Oliver Healthcare Packaging Company is building a manufacturing facility in Johor, Malaysia, to expand its manufacturing operations in the Asia-Pacific region.

It will be the company’s first plant in Malaysia and the largest in Asia.

The facility will support the growth of Malaysia’s pharmaceutical and medical device industry by supplying innovative flexible packaging solutions in Asia-Pacific. It is expected to be operational by the end of 2024.

The Malaysian Investment Development Authority, the Malaysian government’s principal investment promotion and development agency under the Ministry of Investment, Trade and Industry, has been working closely with Oliver for the development of the facility.

The new location is expected to generate job opportunities in the country.

Location

The facility will be situated within AME’s i-Tech Valley, an integrated industrial park located in the economic zone of Iskandar Puteri, Johor.

i-Tech Valley is designed to support business growth and aims to become a leading medical and healthcare hub.

Construction engineering company AME Elite Consortium, through its subsidiary Pentagon Land, has been influential in attracting healthcare multinationals similar to Oliver to establish its manufacturing presence in i-Tech Valley.

The location was strategically selected to serve the significant cluster of pharmaceutical and medical device companies in Malaysia, Singapore, and the rest of Asia-Pacific.

Oliver’s facility also aims to support the company’s regional presence and address future potential supply chain challenges and knowledge gaps in the healthcare sector.

Oliver Healthcare Packaging’s manufacturing facility details

The state-of-the-art facility will be built on a 122,000ft² area in i-Tech Valley.

It will be equipped with the latest manufacturing technology, including ISO-7 and ISO-8 certified clean rooms to meet the stringent regulatory standards for medical packaging.

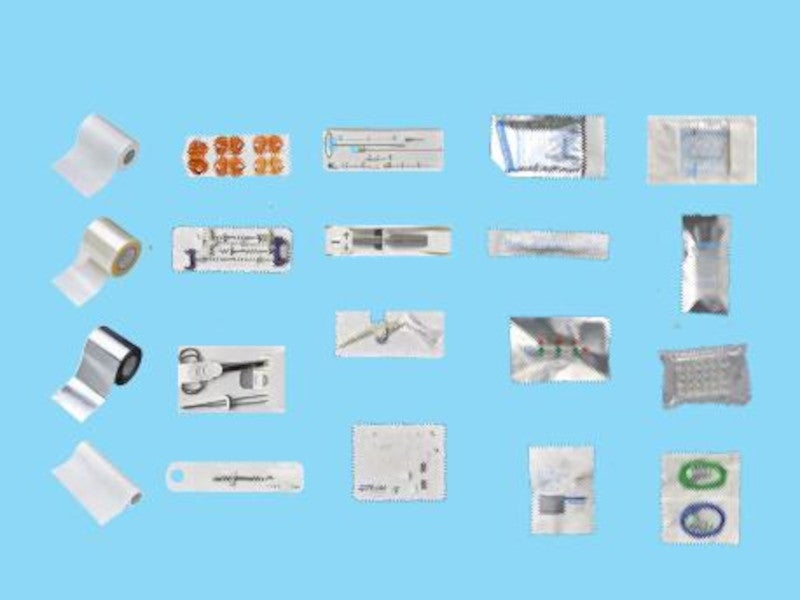

The plant will produce a variety of products such as pouches, medical-grade die-cut lids, high-density polyethylene (HDPE), CleanCut cards, and converted roll stock, and will feature advanced printing technology to support the medical device and pharmaceutical customers in the region.

It will allow Oliver to expand its manufacturing capacity while also enabling it to meet the growing demand of the biopharma, diagnostics, and medical device markets in Asia-Pacific.

Oliver Healthcare Packaging’s product details

Oliver has an extensive product range for the healthcare industry, including pouches, die-cut lids, roll stock, adhesive coatings, HDPE CleanCut cards, forming film, catheter and guidewire dispensers, shippers, and more.

Marketing commentary on Oliver Healthcare Packaging

Headquartered in Grand Rapids, Michigan, US, Oliver Healthcare Packaging supplies sterile barrier packaging solutions.

It employs 1,350 individuals and operates nine manufacturing facilities and six technical labs across various locations in the US, Republic of Ireland, Netherlands, Germany, Switzerland, China, and Singapore.

This includes the recent acquisition of EK-Pack Folien, a manufacturer of high-quality film and foil technology, located in Ermengerst-Wiggensbach, Bavaria, Germany.

The acquisition, made in June 2023, includes Vacopack H. Buchegger, a fully owned subsidiary of EK-Pack, based in north-eastern Switzerland.

Other investments from Oliver have included programmes to regionalise its supply chain, add additional converting equipment, and invest in automation technology.