Finnish-Swedish forestry and biomaterials company Stora Enso announced plans to build a consumer board and pulp mill in China in March 2014. The consumer board machine of the facility was started up in May 2016 and the plant was officially inaugurated in June 2016.

The facility produces liquid packaging board and folding boxboard grades for the rapidly expanding Chinese market. The annual board production capacity of the plant is 450,000t.

Liquid packaging board is used for protecting and preserving contents. Effective printing properties make paperboard cartons suitable for carriers and brand builders.

The plant was built within the Tieshangang Port Industrial Zone located approximately 64km outside Beihai, Guangxi Province, China. The total project investment was €800m ($894.2m).

Plant operations are managed by an equity joint-venture (JV) established by Stora Enso with 83% shareholding in the project. IFC owns 5% of the share in the JV, while the other shareholders are Guangxi Forestry Group and Beihai Forestry Investment & Development Company.

The project also included the construction of a chemical pulp mill. Stora Enso announced its plans to withdraw the plan for the mill from its investment permit in January 2017.

Beihai Mill details

Stora Enso leased 85,000ha of land in Guangxi for eucalyptus plantations and has been managing it since 2012. The Chinese State owns two-thirds of the leased lands.

In October 2008, Tetra Pak announced its plans to build a new packaging plant in India.

The plantations supply wood to the board mill and are located in the Guangxi regions of Beihai, Nanning, Yulin and Qinlian. The plantations are certified by the Forest Stewardship Council (FSC) and its Chinese equivalent (CFCC).

Stora Enso also signed an agreement with Kemira to promote responsible water management and community engagement in Guangxi Province.

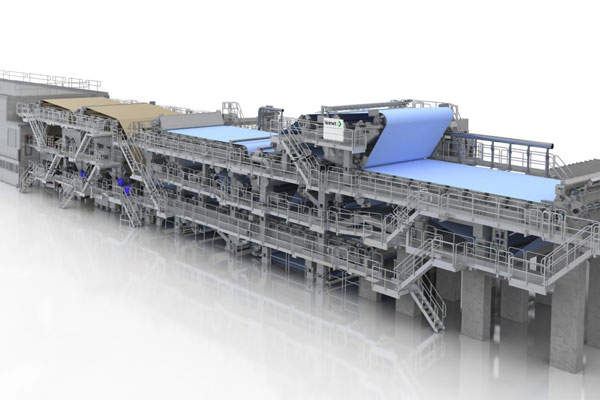

The plant comprises of a bleached chemi-thermomechanical pulp (BCTMP) line and a board production line. These facilities produce high-quality liquid packaging board and folding boxboard grades from eucalyptus.

The board machine also includes a multifourdrinier forming section with a hybrid forming unit, a press, drying and coating sections, a surface sizing unit, a calendar, a reel, two winders and a wide mill engineering package. It also includes related air systems and chemical systems, as well as stock preparation and auxiliary systems.

Benefits of the Stora Enso facility

The facility meets customer requirements for fibre-based renewable packaging.

During the construction phase, the project generated 5,500 jobs. The Stora Enso facility benefits local landowners and the regional economy.

Financing

Stora Enso signed an equity and debt financing agreement comprising an equity investment of CNY356m ($57.78m) with the International Finance Corporation (IFC) for the Beihai facility.

Contractors involved

Valmet supplied the bleached chemi-thermomechanical pulp (BCTMP) line and a board production line for the Beihai mill under a €115m (approximately $158.2m) contract.

Fluor was in-charge of the procurement and construction management services for the Beihai facility and associated infrastructure such as power, water and effluent treatment facilities.

Marketing commentary on Stora Enso

Stora Enso is an integrated paper, biomaterials, wood products and packaging company located in Helsinki, Finland. The company has approximately 29,000 employees supporting operations in 17 countries worldwide.