Wagner Frozen Foods introduced a new state-of-the-art robotic packaging line at its pizza production facility in Braunshausen, Saarland, Germany, in the final quarter of 2003. This line was incorporated in order to increase the speed and efficiency of the packaging system for its mini pizza snack range, Piccolinis.

The more efficient packaging system introduced has led Wagner to increase its output of Piccolinis to over 1.2 million per day. Wagner’s investment for the new SIG Delta robotic system and its installation and maintenance totalled €10.2 million.

BACKGROUND

The demand for the Piccolinis from the German and European markets has grown steadily since their introduction in 1996. During 2003, it was determined that the bottleneck in the production process was the packaging of the product. At its peak, the production facility produces 900 Piccolinis per minute. This requires technology capable of packaging 300 boxes per minute, as there are three Piccolinis pizzas in a box.

The company decided to find new technology to fit their product rather than adapting the product to fit available technology. The system was required to achieve packaging rates of more than 300 boxes per minute and to fit into limited space at the Piccolinis production facility.

MINI PIZZA PACKAGING SYSTEM

Wagner chose SIG Pack Systems to solve this cartoning problem. Wagner already had a SIG HMB Pillow Pack Machine as the centre of its Piccolinis packaging system, which was installed in early 2003. The new robotic system from SIG offered full compatibility with the existing SIG HMB Pillow Pack Machine.

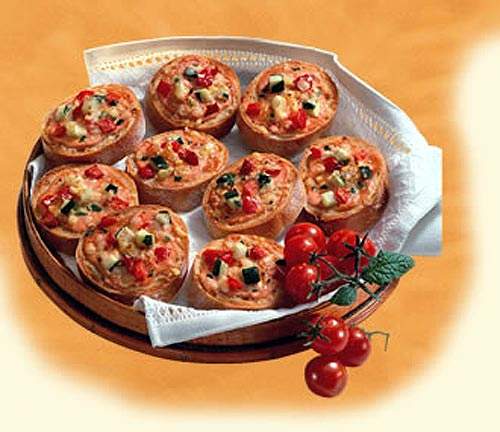

The Piccolinis are packaged in clear plastic pillow triple packs on the SIG HBM Pillow Pack Machine. These packages are then spread across three lanes of a conveyor system and are transferred to the cartoning process. The cartons are provided as preprinted flat forms and are then formed on site.

The new system comprises three SIG Delta robots. Each of the robots is capable of placing more than 100 triple Piccolinis packs a minute into the ready-formed pizza boxes from the carton former. The packages are detected using a vision system with image processing, which enables each robot to locate each package accurately and place it into a carton. Each of the robotic arms matches the speed of the conveyor belt to ensure an accurate, centred pick-up of the product packages. The system was designed to ensure an equal workload of all three SIG Delta robots by giving an even distribution between packages.

At the final process of the system, the boxes are closed, sealed, cased and palletised.

The system is based upon the SIG Systegra system, which is a fully integrated modular packaging system that allows the customer to add or upgrade as required for future expansion. The maintenance contract includes the use of SIG online e-servicing, which allows faults to be diagnosed and solved via the internet, without an engineer having to visit the facility. The technical section of Wagner Frozen Foods is examining the company’s own processes to determine if robotic technology can be applied elsewhere to save time and increase output.

SIG DELTA ROBOT SPECIAL FEATURES

To withstand the high-speed oscillatory movements used by the robots, SIG introduced special mineral castings that consist of a mix of minerals and bonding materials based on epoxy resins. With vibration damping up to 15 times that of steel or grey cast iron, it is only the introduction of these castings that has enabled the more flexible construction, and therefore the column-type suspension, to be developed. A further advantage over other materials is an easy-to-clean, chemically inert surface, which prevents corrosion and provides a robust wash-down unit to satisfy the hygiene requirements.

Input from the SIG industrial design team has also eliminated many horizontal surfaces and given greater floor clearance to reduce cleaning to a minimum. As a finishing touch, an antimicrobial protective layer is permanently bound to the mineral castings to prevent the spread and growth of micro-organisms. The mineral casting also allows an almost infinite choice of form and colour to provide an attractive design without the extra cost of any finishing work.

Moreover, the SIG Delta robots are compliant with IP 65 and NEMA 4X as standard. Optimum accessibility and visibility is provided through large-scale safety doors, and the separation of each individual robot working area offers maximum safety and system availability.