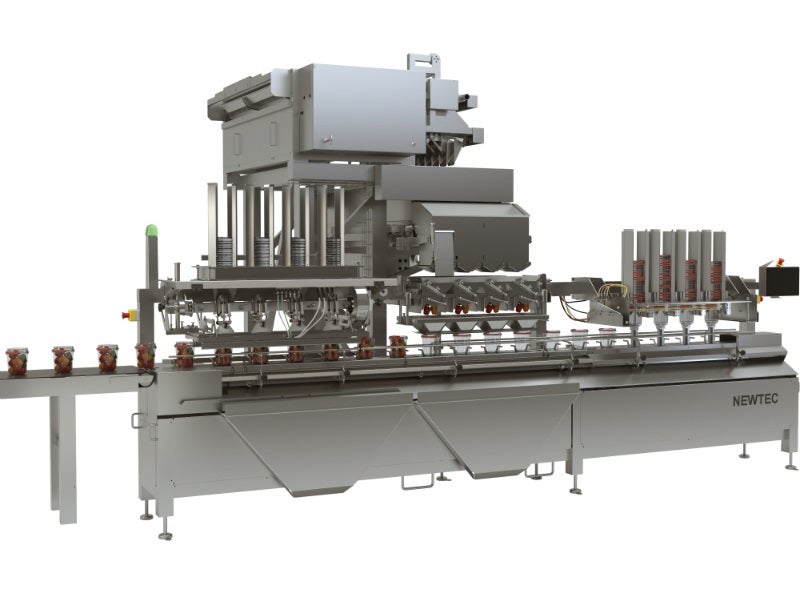

The HSCF can be easily adjusted to pack a diverse range of products, from harder items such as nuts and candies to softer and more fragile foods such as cherry tomatoes and blueberries. The solution is capable of filling containers in various dimensions with or without lids.

Newtec has designed a tool for each container type and while covering complex functions each tool is very easy to change from running e.g. clamshell trays to buckets. It has achieved this by using the following three units: the denester, the filling chute and the closing unit, which are all exchangeable.

The cost-effective system is operated by an intuitive interface, which is an important factor, as well as the easy access for cleaning and servicing if you are changing your production many times a day.

Designed with speed in mind

Newtec mechanical engineer Mathias Theil Pedersen worked on the solution’s development.

The solution represents a fully automatic system from start to finish and is just one example of how Newtec can streamline your applications and increase your bottom line.

“It’s highly flexible and it offers high-capacity and high-speed,” he says. “That’s the main advantage of this machine. The high flexibility comes from the concept of having a basic machine where you add a set of unique tools depending on your preferred container types.

“This means that you don’t need to buy a completely new machine if you get a new packaging material. That’s a big advantage.”

However, the machine has been designed specifically to deliver higher levels of speed.

“Speed was quite a big thing for this machine,” adds Mr Pedersen. “That was the main goal. With other machines, we are doing about 70 or 80 packs a minute. We can do up to 100 packs a minute with this one.

“Customers will experience a higher speed, they will notice a lot more production than normal.”

Keeping up with new orders

The project to develop the HSCF started two years ago following requests for increased speed from clients, with the machine built around a year later.

“We always develop new machines based on request and interest from customers,” Mr Pedersen says. “Of course, they have an interest in getting the machines as quickly as possible when they get in touch with us. Often, our customers are taking a big automation step forward and can’t wait to start optimising their production.

“So there’s a bit of pressure when we are in the innovation phase aiming for the best quality on the market and working hard to exceed the expectations of our customers. For me, it is so rewarding to visit the customer after the installation for the final fine-tuning and see how their vision has been realised.”

Despite being able to operate at higher speeds, the HSCF’s energy consumption isn’t any higher than current machines on the market.

As of May 2019, four machines have been installed so far. Mr Pedersen says the feedback has been highly positive and there are more orders to follow.

This adds to Newtec’s total of installing more than 15,000 machines during the last 40 years.