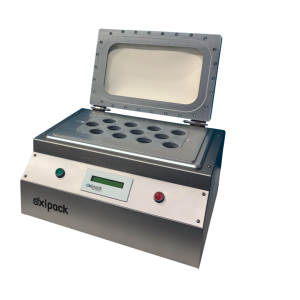

Multi Leak Tester (MLT)

The Oxipack Multi Leak Tester (MLT) is a high-precision solution designed for detecting leaks in a variety of rigid packaging formats. It provides non-destructive, accurate testing for products such as pods, capsules, cans, jars, bottles, vials, and cups. With its vacuum decay method, the MLT ensures the highest level of quality control, safeguarding products while minimizing waste.

Key Features of the Multi Leak Tester (MLT)

- Non-Destructive Testing: The MLT uses a non-destructive method to detect leaks, ensuring that tested packages can be returned to the production line if no leaks are found. This method preserves the contents and packaging, reducing product waste and contributing to cost savings.

- Versatility in Testing Rigid Products: The MLT is highly adaptable and designed to handle a wide variety of rigid packaging, including pods, capsules, and bottles. Its flexibility makes it a valuable asset across multiple industries, from food and beverage to pharmaceuticals.

- Custom-Fitted Testing Chambers: To ensure precision, the MLT uses pre-formed testing chambers that match the exact shape of the packaging being tested. This allows the MLT to embrace the pack securely, protecting its contents while conducting leak detection. This customization enhances accuracy in detecting both large and micro leaks.

- Accurate and Immediate Results: Results are delivered in real-time with a simple pass/fail indicator, providing immediate feedback on package integrity. This efficiency improves overall production line speed and ensures that only leak-free products proceed to the market.

Technical Specifications

- Dimensions and Weight: 465 x 305 x 330 mm (L x W x H); 10 kg

- Materials: Powder-coated steel, anodised aluminium, polycarbonate, onyx

- Power Supply: 100 – 240 VAC/kW

- Air Supply: > 5.5 – < 8 bar

- Compliance: IP40 rated

- Leak Detection Method: Vacuum decay (ASTM F2338)

- Maximum Testing Capacity: 2P/M

Applications in Various Industries

The MLT is ideal for industries that require rigorous packaging standards, such as:

- Pharmaceuticals: The MLT’s precision ensures the integrity of pharmaceutical packaging, helping manufacturers comply with regulatory standards for drug safety.

- Food and Beverage: The MLT protects the freshness and quality of consumable products by detecting leaks that could cause contamination.

- Cosmetics: For beauty products packaged in jars and bottles, the MLT ensures that seals are secure, preventing leakage and preserving product consistency.

Environmental Impact and Cost Efficiency

In line with Oxipack’s commitment to sustainability, the MLT minimizes waste through non-destructive testing. By allowing packages that pass the test to remain in the production line, companies can reduce material loss and lower operational costs, all while maintaining product quality.

The Oxipack Multi Leak Tester (MLT) is a powerful machine for businesses seeking precision, efficiency, and sustainability in their packaging processes. With its vacuum decay method, real-time results, and adaptability across multiple packaging formats, the MLT stands out as a critical component for ensuring the highest standards in product quality.