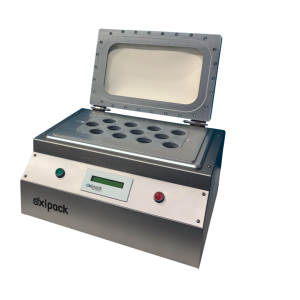

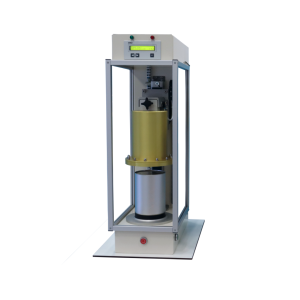

Can Leak Tester (CLT)

The Oxipack Can Leak Tester (CLT) is a specialised tool designed for the precise, non-destructive detection of leaks in various types of cans. Whether dealing with metal or composite carton cans, the CLT ensures product safety and integrity by utilising the vacuum decay method. This versatile solution is ideal for industries such as food and beverage, pet food, and pharmaceuticals, where maintaining airtight packaging is critical to product quality.

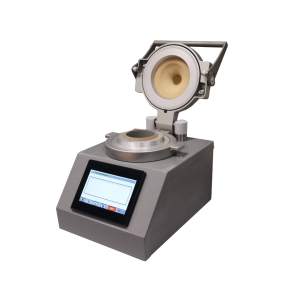

How the CLT Works

The CLT employs the vacuum decay method, which detects pressure changes in a sealed test chamber to identify leaks. A bell jar containing a flexible rubber membrane drops over the can, creating a vacuum in the surrounding space. If there is a leak, the machine registers a pressure difference, indicating compromised packaging.

Key Features of the CLT

- Non-Destructive Leak Detection: The CLT ensures packaging remains intact during testing. This non-destructive approach allows you to reuse packages if they pass the test, reducing waste and operational costs.

- Versatility Across Can Types: The CLT can handle multiple can types, including metal and composite cans, with or without labels. Its patented, FDA-approved flexible membrane is pre-formed to match the exact shape of your packaging, protecting the seal and contents during testing for both micro and large Leaks. Whether detecting micro-leaks or larger breaches, the CLT provides precise, real-time feedback. Its ability to detect leaks as small as 0.9 cm³/min makes it ideal for ensuring product integrity across a wide range of packaging formats.

- Different Sizes and Weights: The CLT is equipped with interchangeable clock heads, allowing quick and efficient testing of different can sizes and filling weights. This flexibility makes it suitable for various industries that rely on canned products.

Technical Specifications

- Dimensions and Weight: 580 x 400 x 878 mm (L x W x H); 62 kg

- Materials: Powder-coated steel, anodised aluminium, polycarbonate, rubber

- Power Supply: 100 – 230V 50/60HZ

- Air Supply: > 5.5 – < 8 bar

- Compliance: CE IP40

- Leak Detection Method: ASTM F2338 (vacuum decay)

- Minimum Leakage Detection: > 0.9 cm3/min

- Maximum Testing Capacity: 2P/M

- Connections: USB/Ethernet export, 24VDC logic (free programmable)

- Supported Can Sizes: Standard can diameters include Ø83 mm, Ø99 mm, Ø127 mm, Ø153 mm.

Applications in various industries requiring high standards in can packaging:

- Food and Beverage: Ensures cans containing fruit, vegetables, or beverages are properly sealed, maintaining product freshness and safety.

- Pharmaceuticals: Critical for packaging drugs in metal cans, the CLT ensures product safety by preventing contamination.

- Pet Food: Guarantees the packaging integrity of canned pet food products, ensuring long shelf life and product safety .

Sustainability and Waste Reduction

Oxipack’s sustainable practices by reducing packaging waste through non-destructive testing. By ensuring leak-tightness without damaging the product, the CLT helps manufacturers cut down on waste while maintaining quality control standards .

The CLT is the ideal solution for businesses that rely on reliable and accurate can packaging. Its versatile, non-destructive testing capabilities make it an important tool for maintaining product quality across industries.