KRELUS AG is a leading manufacturer and supplier of custom-made infrared radiation systems for a wide range of industries and applications.

Specific applications include:

- Thermoforming

- Textile, film, paper and foil coating

- Embossing calendars

- Laminating machines

- Pre-drying and heating equipment

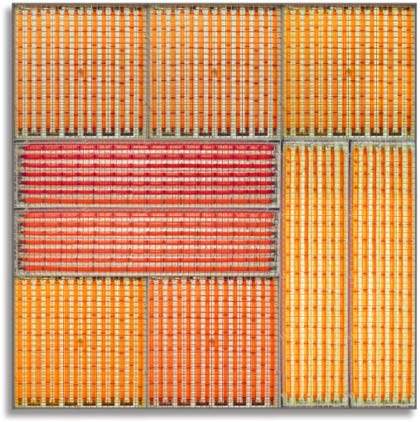

MEDIUM WAVE INFRARED HEATERS – KRELUS IR

The unique technology used in the fast medium-wave KRELUS IR heater allows operation with precise temperature control. These infrared heaters have very rapid reaction time, which allows them to be switched on and off for brief periods to allow energy savings in comparison to traditional radiation systems.

KRELUS IR heater systems are suited to a range of applications, including:

- Evaporation of liquids

- Drying inks

- Melting plastics

- Installation in ovens and drying tunnels

- Speed improvement on existing production lines

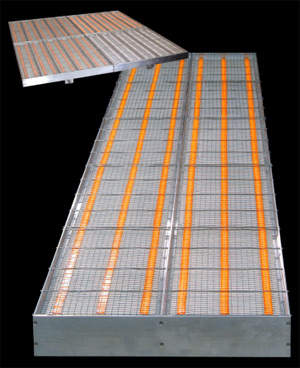

STANDARD INFRARED HEATING MODELS

The company have recently added two standard models of made-to-measure KRELUS IR infrared heaters. These use identical technology, and are available in sizes 248mm x 248mm, 123mm x 496mm and 123mm x 248mm. Power densities of 26kW/m², 32kW/m² or 40kW/m² are available.

The two new types of heater module allow clients to construct individually controlled radiation zones in any desired size. These are particularly suited for use in thermoforming equipment.

MAINTENANCE

KRELUS IR infrared heaters require virtually no maintenance, as they have no moving parts. Any necessary foil replacement can be easily achieved by the client’s own personnel.

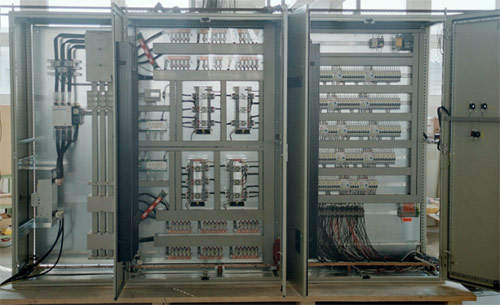

ELECTRONIC HEATER OUTPUT CONTROLS

Electronic controls allow the user to regulate heater output continuously on any of the following principles:

- Machine speed

- Humidity (measured by probe)

- Temperature (measured by probe)

- Optical pyrometer

- Manual regulation by potentiometer

KRELUS INFRARED DRYING SYSTEMS FOR PRINTING INKS

Designed for drying printing inks and water-based varnishes on sheet-fed printing presses, KRELUS offers a wider range of custom-made solutions. The KRELUS infrared dryer for normal printing inks has been installed more than 2,500 times. It shows a

number of advantages, compared to so-called lamp dryers, including:

- Fast on / off reaction

- Self-cleaning function

- Pure IR heat, no eye irritation from bright light, and optimal absorption of heat energy on printed sheet

- Low energy consumption

- Excellent price / durability / performance ratio

KRELUS AIR-DRYING FOR WATER-BASED VARNISHES

For water-based varnishes, KRELUS offers the AIRTHERM system. This is a combination of the famous infrared dryer and a hot air system. AIRTHERM fits perfectly into almost all sheet-fed presses with extended delivery. Benefits of the AIRTHERM system

include:

- Precise guidance of hot air to the varnished sheet

- Efficient varnish drying

- Continuous control of air volume and air temperature

- Various configurations available