LasX Industries manufactures high-quality laser converting equipment ideally suited to the packaging industry to achieve applications including:

- Easy-open features in pouches, bags and pour spouts

- Breathable and modified atmosphere packaging

- Peel / reclose applications

- Microwave steam-release features

- Folding cartons

- Labels

- Print media

Patented LaserSharp® digital converting technology achieves multiple processes in a single production run at high production speeds. LaserSharp systems accurately cut, score, perforate, kiss-cut and etch papers, plastics and adhesives with unmatched precision.

Laser processing for flexible packaging

Laser processing is ideal for flexible packaging applications including tear strips, pour spouts, microwave steam release features, and modified atmosphere packaging (MAP). The non-contact laser process vaporizes materials at controlled depths, resulting in precise score lines registered to print, and cleaner, more uniform perforated holes.

LaserSharp technology is also suitable for kiss-cutting pressure-sensitive labels, and through cutting intricate shapes or functional features in printed materials and folding cartons. LaserSharp digital technology eliminates the downtime, cost and tool wear associated with traditional mechanical processing methods. This ‘direct to part’ processing allows for a completely on-demand, digital workflow across the production floor, perfect for both cost-effective short runs as well as full-scale production.

LaserSharp systems easily integrate into new or existing production lines and can be retrofitted to equipment such as slitter-rewinders and pouch machines. Systems can be configured in roll or sheet-fed formats and offer straight line, contour and patterned processing in both down-web and cross-web directions. Because laser converting is a completely digital process, design changes can be made on-the-fly by adjusting a vector file which guides the path of the laser.

Perforating and scoring systems

Advantages of LaserSharp perforating and scoring systems include:

- Non-contact, fast, clean, high-quality processing method

- No consumables or tool wear

- Low maintenance

- Highly flexible digital process enables any pattern

- Adjustable process areas with automatic focus assembly

- Process patterns, straight lines, or contoured lines in both cross-web and machine directions

- Precise digital control for processing thin materials at high speeds

- Eye mark and encoder registration capabilities

- Standard modules easily integrate into existing or new material handling systems

- Patented Foresight® controls

- Process-on-the-fly enables controlled-depth processing independent of material speed

Sheet-fed systems for folding cartons and print media

Benefits of LaserSharp sheet-fed systems for folding cartons and print media include:

- Unlimited cutting paths without shape limitations

- Achieve complex designs and patterns with high tolerances

- Digital finishing requires no hard tooling or metal dies

- Reduced time to market

- Instant order change on-the-fly

- Product personalization, ideal for custom orders

- Waste reduction

- Streamlined workflow

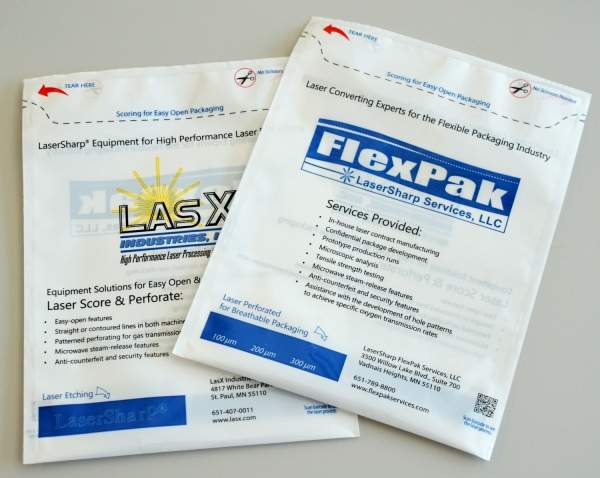

Contract laser converting services

LasX’s partner, LaserSharp FlexPak Services, uses LaserSharp technology to offer contract laser converting services to the flexible packaging industry. LaserSharp FlexPak Services is a premier toll converter, dedicated to developing innovative laser solutions for the design, testing and production of easy open and breathable flexible packaging.

Customers are provided with complete technical support, from prototype to full-scale production, resulting in an accelerated time to market and reduced development costs. Production operates in a food grade, ISO 9001:2008-certified facility which houses five roll-fed LaserSharp systems, ensuring superior quality of laser processed flexible films.

Together, LasX Industries and FlexPak Services offer the widest range of system and service solutions to accommodate the short run or high volume production of your unique packaging applications.